Components and spare parts for ion implantation

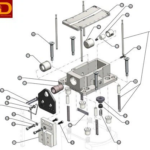

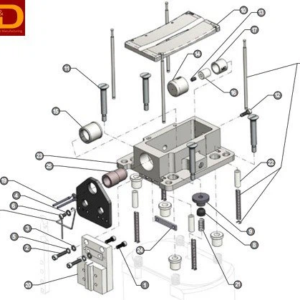

Ion implantation is an important process during the manufacture of semiconductors. Implanters dope wafers with “foreign atoms” in order to modify material properties such as conductivity or crystal structure. The heart of an implanter system is the beam path. Here, the ions are generated, concentrated, accelerated dramatically, and guided at high speed to the wafer.

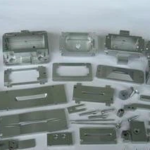

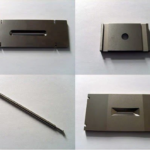

Temperatures of up to 1400 °C, strong electromagnetic fields, aggressive process gases, and powerful mechanical forces cause problems for conventional materials. But not for our products. Our heat-resistant components made from molybdenum, tungsten, graphite or ceramics excel due their ideal combination of corrosion resistance, material strength, high thermal conductivity and absolute purity. 100 or more T&D components are at work in every beam path. They ensure that the ions are generated efficiently and guided precisely and free from impurities along the beam path to the wafer.

Accurate to a thousandth of a millimeter and with more than 30 years of experience in the semiconductor industry, we produce components that conform precisely to the OEM standard or further develop these components at our production sites in Japan and the USA. Because, for our customers in the semiconductor industry, T&D spare parts are increasingly becoming more than just spares. Taking the equipment manufacturer’s original spare parts as our starting point, we optimize the geometries and material compositions.

The benefits to you:

- Simplified component installation and removal

- Longer service lives

- Lower cleaning costs

- Reduced maintenance work

- Reduced downtimes

We know how important reproducible quality is for your process. Which is why we make sure that our quality is exceptional. Every single time. How do we do it? We have been manufacturing high-performance materials since 1997 and handle every stage of the production process ourselves – from the metal powder through to the finished product. Only implanter components that pass our rigorous quality controls are allowed to leave our factory.

Our products.

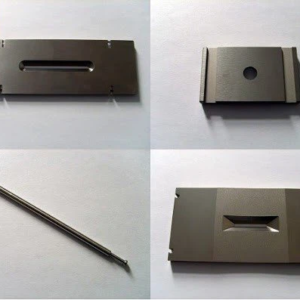

- Chambers (tungsten, molybdenum and alloys)

- Filaments (tungsten and tungsten alloys)

- Arc slits (tungsten, molybdenum and alloys)

- Holders (tungsten, molybdenum and alloys)

- Cathodes (tungsten, molybdenum and alloys)

- Spare parts (tungsten, molybdenum and alloys)