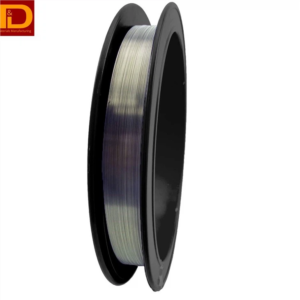

Tungsten Wire is mainly used as filament in an incandescent lamp. An incandescent lamp heats a tungsten wire to incandescence using heat radiation that emits visible light, and the filament in an incandescent bulb is made of ultra-thin tungsten wire.

The normal working temperature of the lamp reaches more than 2000℃, which is not enough to reach the melting point of the tungsten wire 3370℃, but this high temperature can make a part of the tungsten wire surface atoms evaporate.

Incandescent-lamp

The chemical properties of tungsten filament are very stable and strong in oxidation resistance, and should not be changed with other substances in the air, which enhances the life of the tungsten bulb.

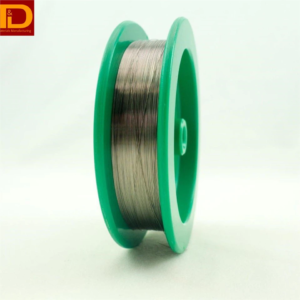

Tungsten wire is also used as an electrode wire in photocopiers. The main type used is gold-plated tungsten wire, which refers to the tungsten wire coated with a layer of gold. It is a special tungsten wire, and the main purpose of gold plating is to prevent corrosion.

Regarding its surface characteristics, gold-plated tungsten wire exhibits enhanced beauty with a brighter appearance compared to wolframite, scheelite, and sprayed tungsten wire. Delving deeper, the corrosion resistance of gold-plated tungsten wire significantly surpasses that of standard tungsten wire.

On top of the electrodes used in photocopiers, gold-plated tungsten wire can also be used as an ideal corrosion-resistant electron emission material.

In addition to a small amount of tungsten wire used as heating materials in the high-temperature furnace, heating elements of electron tubes, and reinforcing bars of composite materials, most of the tungsten wire is used for making various filament of incandescent lamps, iodine tungsten lamp and electrode of the gas discharge lamp.

The tungsten filament made by forging and drawing tungsten wire is mainly used in incandescent lamps, halogen tungsten lamps, and other electric light sources. Iodine tungsten lamps have the characteristics of high brightness and a long life. Ordinary iodine tungsten lamps are often used as a lighting source for cinematography, stages, factories, buildings, and squares.

Lodine tungsten lamps not only reduce the evaporation of tungsten and extend the service life, but they also improve the working temperature and luminous efficiency. In size, the iodine tungsten lamp is very small and delicate.

The same 500-watt bulb is only 1 percent of the volume of an incandescent bulb. In addition to iodine, the glass shell is filled with inert gas, which is small and strong. The gas pressure is up to 1.5 to 10 atmospheres.

Tungsten wire is employed as a heating element for recharging lighters. In this application, it substitutes flint and fuel, with resistance coils and small batteries operating akin to car cigarette lighters. Furthermore, a noteworthy advantage for IT professionals working at their computers is that the device’s battery can be conveniently charged via the USB port.

The excellent heat resistance of it greatly improves the performance of charging the lighter. The tungsten wire heats up when the switch is turned on, and when it is red, it can be used to light cigarettes. It can play a role in combustion, generally without an obvious flame. The ordinary flame lighter is a direct combustion steam body, which has the obvious flame to blow out. Tungsten is usually used to make filaments because it has a high melting point and does not fuse easily.

Electricity is used to heat the tungsten wire, causing the air to expand. When the air reaches a specific pressure, it is released in a burst. Cigarette lighters utilize compressed butane gas, converted into a liquid state to reduce its volume. This process offers the benefit of making the gas easier to store and transport due to its reduced volume.