Pure Tungsten Electrode

Pure tungsten electrodes are suitable for welding and widely used under alternating current.

| Electrode Name | Trade mark |

Added impurity |

Impurity quantity |

Other impurities |

Tungsten | Electric discharged power |

Color sign |

| Pure Tungsten Electrode | WP | — | — | <0.20% | The rest | 4.5 | Green |

Thoriated tungsten Electrode

Thoriated tungsten electrodes are the most commonly used tungsten material, Thoria is a low-level radioactive material but in certain situations, it is significantly better than pure tungsten electrodes. Thoriated tungsten electrodes are generally used for DC applications, as they operate well even when overloaded with extra amperage, and then improve the performance of welding.

| Trade mark | ThO2 Content(%) | Color sign |

| WT10 | 0.90 – 1.20 | Primary |

| WT20 | 1.80 – 2.20 | Red |

| WT30 | 2.80 – 3.20 | Purple |

| WT40 | 3.80 – 4.20 | Orange Primary |

|

|

|

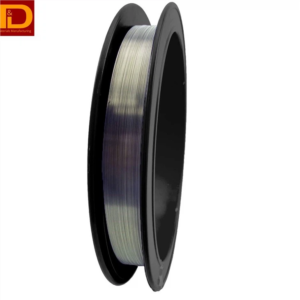

| (Thoriated tungsten Electrode) | (Cerium–tungsten Electrode) |

Cerium Tungsten Electrode

Cerium tungsten electrodes exhibit strong initial arc performance when operating at low current levels. As the arc current is low, these electrodes can be used for welding pipes, stainless steel, and fine parts. Cerium tungsten is the best substitute for thoriated tungsten under the condition of low DC.

| Trade mark | Added impurity |

Impurity quantity |

Other impurities |

Tungsten | Electric discharged power |

Color sign |

| WC20 | CeO2 | 1.80 – 2.20% | <0.20% | The rest | 2.7 – 2.8 | Grey |

Lanthanated Tungsten Electrode

Lanthanated tungsten electrodes have become more popular in the world of welding shortly after they were developed. The electric conductivity of lanthanated tungsten electrodes is closest to that of 2% thoriated tungsten electrodes. Welders can easily replace thoriated tungsten electrodes with lanthanated tungsten electrodes at either AC or DC. The radioactivity from thoriated tungsten electrodes can thus be avoided. Another advantage of lanthanated tungsten electrodes is being able to bear a high current and having the lowest burn-loss rate.

| Trade mark | Added impurity |

Impurity quantity |

Other impurities |

Tungsten | Electric discharged power |

Color sign |

| WL10 | La2O3 | 0.80 – 1.20% | <0.20% | The rest | 2.6 – 2.7 | Black |

| WL15 | La2O3 | 1.30 – 1.70% | <0.20% | The rest | 2.8 – 3.0 | Yellow |

| WL20 | La2O3 | 1.80 – 2.20% | <0.20% | The rest | 2.8 – 3.2 | Sky blue |

Zirconiated Tungsten Electrode

Zirconiated tungsten electrodes have a strong performance in AC welding, especially under high load current. These electrodes can retain a balled end when welding, which results in less tungsten permeation and good corrosion resistance. Our technical staff has been engaged in research and testing work and succeeded in solving the conflicts between zirconium contents and processing properties.

| Trade mark | Added impurity |

Impurity quantity |

Other impurities |

Tungsten | Electric discharged power |

Color sign |

| WZ3 | ZrO2 | 0.20 – 0.40% | <0.20% | The rest | 2.5 – 3.0 | Brown |

| WZ8 | ZrO2 | 0.70 – 0.90% | <0.20% | The rest | 2.5 – 3.0 | White |

|

|||

| (Zirconiated tungsten Electrode) |

Yttrium Tungsten Electrode

Mainly applied in the military and aviation industry with narrow arc beams, high compressing strength, and highest welding penetration at medium and high current.

| Electrode Name | Trade mark |

Added impurity |

Impurity quantity |

Other impurities |

Tungsten | Electric discharged power |

Color sign |

| Yttrium-Tungsten Electrode | WY20 | YO2 | 1.80 – 2.20% | <0.20% | The rest | 2.0 – 3.9 | Blue |

Composite Tungsten Electrode

Their performances can be much improved by adding two or more rare Earth oxides that are mutually complementary.

| Electrode Name | Trade mark |

Added impurity |

Impurity quantity |

Other impurities |

Tungsten | Electric discharged power |

Color sign |

| Composite Electrode | ReOx | 1.00 – 4.00% | <0.20% | The rest | 2.45 – 3.1 |