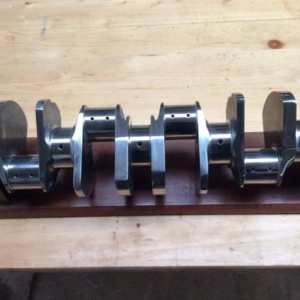

Heavy Tungsten Alloy Balance Weight for Crankshaft

Tungsten alloy crankshaft balancing, often informally referred to as the crank, is an integral aspect of an engine. It converts the reciprocating linear motion of the pistons into rotational motion, serving as a vital link between the piston rods and the car’s flywheel. Essentially, the crankshaft transforms piston movement into power for the vehicle. It is responsible for the rotation of piston motion while the engine part connects to the flywheel and employs crank throws to link the connecting rods to the cylinders.

How Does Crankshaft Balancer Work?

The rods and bearings connect the piston to the crankshaft, when the piston moves up and down, it is moved as describing a circle by the rods and bearings, then, it is rotating.

Advantages of Tungsten Alloy Crankshaft Balancer

It is necessary to provide counterweights for the reciprocating mass of each piston and connecting rod to improve balance in engines, and these are typically cast as part of the crankshaft. Lead is cheap, but it is much less dense than heavy tungsten alloy and is not environmentally friendly. As for steel, tungsten alloy is more than twice its density. So compared with other materials, heavy tungsten alloy is considered the most appropriate crankshaft material for its properties as follows:

- Small volume but high density

- Excellent hardness

- Superior wearing resistance

- Good corrosion resistance

- Wonderful Shock resistance

- High melting point

- High-temperature resistance

- Environmentally friendly

Crankshaft balancing is crucial to engine performance. In race cars, aircraft, or other high-performance engines, professionals who are serious about crankshaft balancing rely on T&D to provide the high-quality tungsten weights they need.

Regarding Density:

Density of D17 tungsten = 17 grams/cc

Density of steel = 7.83 grams/cc

To determine the weight of high-density tungsten or steel:

Weight (grams) HD tungsten = Dia2(inches) x 12.87 x Length(inches) x 17

Weight (grams) steel = Dia2(inches) x 12.87 x Length(inches) x 7.83

When switching from steel to tungsten weights, every gram of steel removed is replaced with 2.17 grams of tungsten. You have therefore increased the weight by 117%.

Example:

If you drill out 90 grams of steel and replace it with tungsten, you’ve replaced 90 grams with 195.3 grams. The net additional weight will be 105.3 grams.

195.3 – 90 = 105.3 grams

An easy way to calculate the net additional weight added when using tungsten is to multiply the grams of steel removed by 1.17.

90 x 1.17 = 105.3 grams added weight

The cost of tungsten weights will be higher because of additional material normally added to the length.

We suggest you overbalance slightly and remove material to fine-tune crankshaft balancing.

Crankshaft balancing isn’t always an easy process, but the added value to engine performance is well worth the effort. Let the experts at T&D help you apply the best tungsten weights available to solve even your most challenging crankshaft balancing issues.