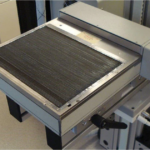

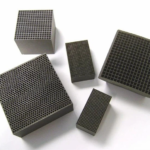

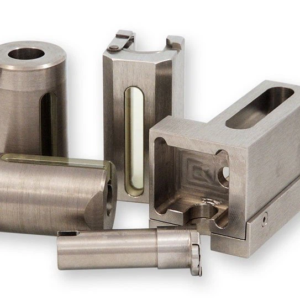

Tungsten Alloy Collimator

In the realm of industrial radiography using gamma radiation sources like Iridium-192 or Cobalt-60, a collimator serves as a tool for the radiographer to regulate the exposure of radiation, thereby exposing a film and generating a radiographic “negative” or radiograph. This process is used to inspect materials and identify defects. Typically made from tungsten, the collimator is rated based on the number of half value layers (HVL) it contains, which indicates how many times it reduces undesirable radiation by half. For example, the thinnest walls of a 4 HVL tungsten collimator, which is 0.52 inches thick, will decrease the intensity of radiation passing through them by 88.5%. The design of the tungsten alloy collimator enables the radiographer to precisely direct the radiation toward the film while diverting it away from other workers.

Tungsten Alloy Collimator Application

In the realm of industrial radiography using gamma radiation sources like Iridium-192 or Cobalt-60, a collimator serves as a tool for the radiographer to regulate the exposure of radiation, thereby exposing a film and generating a radiographic “negative” or radiograph. This process is used to inspect materials and identify defects. Typically made from tungsten, the collimator is rated based on the number of half value layers (HVL) it contains, which indicates how many times it reduces undesirable radiation by half. For example, the thinnest walls of a 4 HVL tungsten collimator, which is 0.52 inches thick, will decrease the intensity of radiation passing through them by 88.5%. The design of the tungsten alloy collimator enables the radiographer to precisely direct the radiation toward the film while diverting it away from other workers.

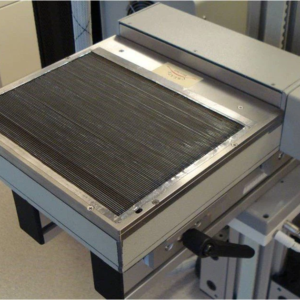

Hence, the utilization of tungsten alloy collimators is extensive in linear accelerators used for radiotherapy treatments. These collimators play a crucial role in shaping the radiation beam emitted by the machine, this lets them limit the maximum field size of the beam. In the treatment head of a linear accelerator, both a primary and secondary collimator are present. The primary collimator is positioned once the electron beam attains a vertical orientation or, when using photons, after the beam passes through the X-ray target. As for the secondary collimator, it is placed following either a flattening filter (for photon therapy) or a scattering foil (for electron therapy). Comprising two movable jaws, the secondary tungsten alloy collimator allows for adjustments to either expand or reduce the size of the treatment field.