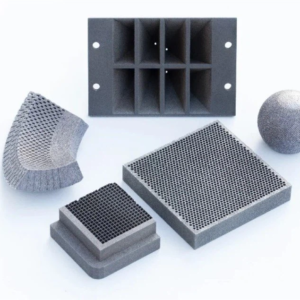

The following can be made by heavy tungsten alloy, tungsten polymer or silicone tungsten.

1: CT Tube Housing

2: X-Ray Tube Housing

3: X-Ray Tank

4: Collimators

5: Detector Shield

6: PET Shielding

7: Accelerator Shields

8: Nuclear Casks

9: Nuclear Waste Storage

10: Apron and Vest

Radiation Shielding

T&D Materials Manufacturing produces highly dense Tungsten Alloys that also have exceptional attenuating ionizing radiation. These alloys are particularly well-suited for shielding applications in nuclear medicine and the nuclear industry. The effectiveness of radiation attenuation is often measured by the ‘tenth layer thickness,’ indicating the plate thickness required to reduce transmitted radiation to one-tenth of the incident radiation intensity. A lower tenth layer thickness signifies superior shielding performance. Additionally, the attenuation properties vary based on the incident energy of the radiation.

Graph 1 illustrates the gamma-ray absorption characteristics of 95WNIFE and compares it to other shielding materials, showcasing the tenth layer thickness in relation to incident beam energy. This data, sourced from the National Physics Laboratory, emphasizes the exceptional shielding qualities of T&D Materials Manufacturing Tungsten Alloys.

Graph 1 – Comparative Absorption Data as a Function of Energy

Comparative Absorption Data

Within the Tungsten Alloy range, the tungsten content ranges from 90% to 97% by weight, with higher tungsten concentrations enhancing radiation attenuation and consequently reducing the tenth layer thickness. Table 1 provides a comparison at a constant incident γ-ray energy (Co60) of absorption data for two T&D products and lead. The table also displays the associated half thicknesses of shielding required to halve the radiation intensity.

Table 1 – Comparative Absorption Data

| 90WNIFE | 95WNIFE | Lead | |

| % Tungsten | 90.0 | 95.0 | 0 |

| Narrow bean Radiation tenth layer thickness, mm | 24.8 | 24.3 | 38.3 |

| Half thickness, mm | 7.5 | 7.0 | 11.7 |

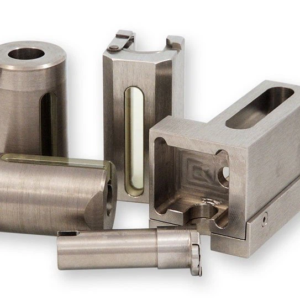

Tungsten Alloy Radiation Shield

For top-notch radiation shielding applications in both medical and industrial sectors, consider Tungsten Alloy Radiation Shield, outperforming traditional materials like lead, and offering exceptional properties. High-density alloy can provide equivalent energy absorption to lead while utilizing only 1/3 less of the material. People have been leveraging the reliable radiation shielding capabilities of tungsten alloy for optimal results in various applications.

Tungsten Medical Radiation Shielding

T&D Materials Manufacturing provides tungsten alloy radiation shields, ideal for applications such as radioactive source containers, gamma radiography, X-ray shields, and industrial instrumentation. Tungsten shielding excels as a collimator and radiation shielding in cancer therapy, offering effective syringe protection for radioactive injections. We typically offer tungsten alloy radiation shielding as per the following standard. Additionally, our expertise extends to designing and creating custom sizes based on specific properties:

| Grade | Application |

| HA170 | HA170 is the most ductile and readily machinable grade. Common application areas include counterbalancing

weights for the aviation and aerospace industries, crankshaft and auto racing cars, bucking bars for rivet setting, and radiation shielding. |

| HA175 | HA175 is commonly used to produce chatter-resistant boring bars and tool shanks as well as radiation shielding

components. |

| HA180 | HA180 is often applied where size is a factor in the placement of balance or ballast weights. It should be typically

of parts with small volume but heavy density. Other applications include radiation shields and collimators of X-ray or gamma-ray beams. |

| HA185 | The densest of the Ni-Fe binder alloys with tungsten, and is the preferred grade for radiation shielding in the medical imaging industry. |

| HA170C | Adding copper as a substitute for iron in the binder phase, as there is a requirement for a nonmagnetic working

environment and is the ideal choice for radiation shielding close to a magnetic field. |

| HA180C | Much denser than HA170C which is used as large shielding in a nonmagnetic working environment. |

Tungsten Industrial Radiation Shielding

Tungsten shielding plays a crucial role in research activities, serving as collimators (devices directing radiation beams) or containers for radioactive isotopes. In nuclear research, where reactors or cyclotrons are used to study or produce radioactive materials, tungsten alloy radiation shielding proves essential for effective protection against both X-ray and Gamma-ray radiation. Boasting a density over 60% higher than lead, tungsten alloy enables a reduction in the physical size of shielding components.

Commonly employed in applications such as Non-Destructive Testing (NDT), tungsten alloy radiation shielding offers optimal radiation protection, making it a valuable asset in diverse research and industrial settings.

Non-Destructive Testing (NDT) methods utilize various techniques, including electromagnetic radiation, sound, and material properties, to examine samples. This examination may involve microscopy to examine external surfaces in detail. While sample preparation techniques for metallography, optical microscopy, and electron microscopy are typically destructive, requiring the surfaces to be made smooth through polishing or achieving electron transparency in thickness, the interior of a sample can be examined using penetrating electromagnetic radiation like X-rays or 3D X-rays for volumetric inspection. Enhance radiation protection against harmful radiation in these processes with the application of tungsten alloy radiation shielding.

Geologing

Geologing is an exploration technique used mainly in the oil and gas industries. It is also known as wireline logging and borehole logging. A gamma ray source is lowered into a borehole and the radiation penetrates the rock strata. This data can then be analyzed to determine whether deposits of gas or oil are present. Tungsten alloy is used to shield the radioactive source and to act as a collimator for the gamma beam.

Pipeline Inspection Gamma

Radiation plays a key role in weld inspection and pipeline crack detection. The process involves a gamma source being mounted to a remote-controlled wheeled trolley, sometimes referred to as a ‘pig,’ traveling through the length of the pipe. To direct radiation onto the target, a tungsten collimator is employed, with the radioactive source securely housed within tungsten shielding.

Why Use Tungsten Alloy Radiation Shielding?

When we design tungsten radiation shielding, it will be calculated according to the requirements of the shield to abate the multiple shielding materials’ thickness:

Formula: K = e0.693 d / ᇞ1/2

K: Shield weakened multiple

ᇞ 1/2: The tungsten nuclear radiation shielding material of the half-value layer values

d: Shielding thickness, with the half-value layer thickness of their units, you need to half-value layer thickness of the quality of translation into the thickness of the material, divided by the density of the material can be obtained. In this way, tungsten alloy radiation shielding could be much thinner to have the same protection ability as other materials such as lead or Al2O3.

Tungsten Radiation Shielding

Why Do We Need Tungsten Alloy Radiation Shielding?

As medical science advances rapidly, the prevalence of tungsten radiation shielding in various aspects of our lives has increased. The widespread use of X-ray equipment in medical instruments and nuclear power stations has a significant impact on society. Individuals must be increasingly mindful of radiation, and institutions play a vital role in safeguarding the public from exposure. This includes ensuring protection against various sources of radiation such as X-ray radiation, gamma radiation (energetic electromagnetic radiation), alpha particles (helium atoms), beta particles (electrons), and cosmic radiation. Heightened awareness and protective measures are essential in this evolving landscape.

For the safety of patients, medical professionals, and individuals at risk of radiation exposure, it’s imperative to securely isolate and shield radiation sources. Ensuring that instruments for holding and delivering radioactive materials maintain low radiation levels is crucial in preventing harmful effects like breast cancer and skin cancer caused by ionizing radiation. While lead and steel are conventional protective materials, opting for tungsten alloy radiation shielding emerges as the optimal solution. Boasting exceptional radiation absorption, superior shielding capabilities with twice the density of lead, and robust physical resistance, tungsten alloy radiation shielding stands out as the premier choice for comprehensive radiation protection.

Advantages of Tungsten Alloy Radiation Shielding

Experts find that radiation exposure could be reduced by maxing shielding.

The radiation protection capability of a material is closely tied to its density, with higher density equating to superior ability to stop and absorb radiation rays. Tungsten radiation shielding, boasting a density surpassing many other materials, excels in absorbing and stopping radiation rays compared to traditional metals like lead. The heightened linear attenuation of gamma radiations in tungsten radiation shielding means that less material is needed for equivalent shielding. Alternatively, equal amounts of tungsten shielding present reduced exposure risks compared to an equivalent quantity of lead, making it a highly effective choice for radiation protection.

Tungsten heavy alloy stands out as the optimal material for radiation protection, thanks to its unique blend of radiographic density (over 60% denser than lead), machinability, excellent corrosion resistance, high radiation absorption (outperforming lead and steel), simplified life cycle, and high strength. Tungsten radiation shielding ensures an equivalent level of protection as lead while significantly reducing overall volume and thickness of shields and containers. Additionally, when compared to lead or depleted uranium (DU), tungsten radiation shielding is more environmentally friendly, as it is non-toxic, making it a preferred choice.