Tungsten Carbide Anvil & Cylinder for Synthetic Diamond

T&D supplies dies, punches, anvils, and backup blocks tailored to your exact dimensional needs. Our products are designed to withstand pressures of up to one million psi, pushing the boundaries of mechanical properties in tungsten carbide materials.

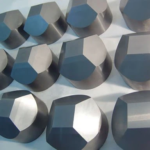

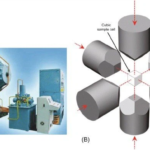

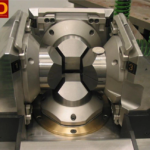

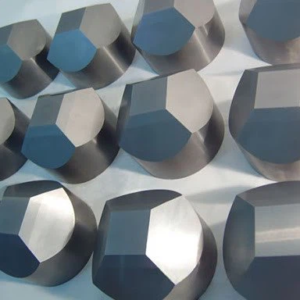

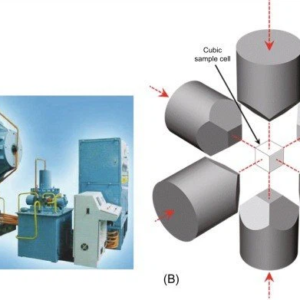

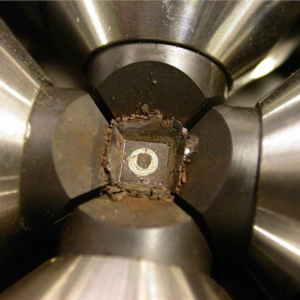

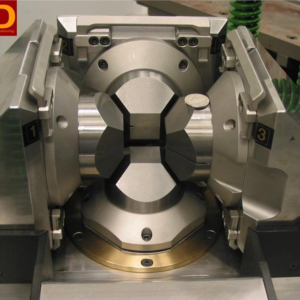

Cemented Carbide Anvil and Cylinder for Synthetic Diamond Manufacturing

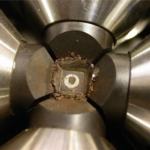

Widely utilized in the artificial diamond powder industry, our anvils and cylinders perform seamlessly under 60,000Mpa pressure conditions. We can assure each product is crafted to the highest quality standards, available in both finished and as-sintered options. Leveraging advanced pressing, sintering technology, and HIP, our manufacturing process eliminates any flaws such as pores and cracks.

At T&D, we specialize in accommodating custom requests, offering customized grades and sizes to match your specific requirements and usage conditions.

Physical & mechanical properties of grades

| Grade | Physical and mechanical properties | Applications recommended | ||

| Density ±0.1g/cm3 | Hardness ±0.5HRA | T-RS N/mm2 | ||

| DN8 | 14.73 | 90.5 | 2700 | For 6-facet anvils |

| YG6 | 14.90 | 91.0 | 2450 | For 2-facet anvils |

| YG12 | 14.31 | 88.5 | 2800 | For pressure cylinders |

Cemented carbide >>> cemented carbide pressure cylinders as sintered

| Type | Dimensions | |||||

| D | H | d | h | a | R | |

| DG250-1 | 171.5+2.5-0.5 | 111.5+2.00 | 49.00-2.0 | 54 | 59 | 24.5 |

| DG250-2 | 207.5+2.5-0.5 | 121.0+2.50 | 49.00-2.0 | 51 | 11 | 30.6 |

| DG241 | 181.5+2.5-0.5 | 108.0+2.50 | 40.00-2.0 | 50 | 11 | 30.0 |

| DG256 | 219.5+2.5-0.5 | 112.0+2.50 | 55.00-2.0 | 54 | 59 | 24.5 |

| DG268 | 281.5+3.5-0.5 | 141.0+2.50 | 67.50-2.0 | 65 | 82 | 25.0 |

Note: The specifications mentioned above are recommended, we also offer sintered and finished machined products tailored to alternative specifications as per customers’ provided technical drawings or samples.

Cemented carbide >>> 2-facet cemented carbide anvils as sintered

| Type | Dimensions | |||||

| D | H | d | h | a | R | |

| DC235 | 83.0 | 76.5 | 35.5 | 47.75 | 60 | 25.4 |

| DC242 | 111.2 | 88.5 | 42.5 | 51.4 | 60 | 24.5 |

| DC260 | 145.5 | 107.5 | 60.5 | 65.0 | 50 | 30.0 |

Cemented carbide >>> Types, dimensions, and tolerances of finish machined 6-facet anvils.

| Series | Type | Dimensions | ||||

| D | E | H | F | β | ||

| Φ103 | GDC6325-1030~1050-1 | 103.0~105.0 | 32.5 | 76.0 | 12.5 | 41° |

| GDC6325-1030~1050-2 | 103.0~105.0 | 32.5 | 83.0 | 11.5 | 41° | |

| GDC6325-1030~1050-3 | 103.0~105.0 | 32.5 | 77.0 | 12.5 | 41° | |

| GDC6330-1030~1050-1 | 103.0~105.0 | 33.0 | 77.0 | 12.5 | 41° | |

| GDC6335-1030~1050 | 103.0~105.0 | 33.5 | 77.0 | 12.5 | 41° | |

| Φ110 | GDC6380 1102 | 110.2 | 38.0 | 80.0 | 13 | 41° |

| GDC6390-1100~1103 | 110.0~110.3 | 39.0 | 80.0 | 13 | 41.5° | |

| Φ114 | GDC6395-1146~1149 | 114.6~114.9 | 39.5 | 82.5 | 13 | 41.5° |

| Φ110 | GDC6365-1150~1155 | 115.0~115.5 | 36.5 | 82.5 | 12.5 | 41.5° |

| GDC6380-1150~1154 | 115.0~115.4 | 38.0 | 82.5 | 12.5 | 41° | |

| GDC6385-1150~1151 | 115.0~115.1 | 38.5 | 82.5 | 14 | 41.5° | |

| GDC6395-1150~1156 | 115.0~115.6 | 39.5 | 82.5 | 13 | 41.5° | |

| GDC639-1150~1153 | 115.0~115.3 | 39.0 | 82.5 | 13 | 41.5° | |

| GDC6400-1150~1159 | 115.0~115.9 | 40.0 | 82.5 | 13 | 41.5° | |

| G DC6400-1152 | 115.2 | 40.0 | 84 | 13 | 41° | |

| GDC6410-1150~1152 | 115.0~115.2 | 41.0 | 82.5 | 13 | 42° | |

| GDC6410-1150 | 115.0 | 41.0 | 82.5 | 13 | 41.5° | |

| Φ122 | GDC6415-1220~1125 | 122.0~122.5 | 41.5 | 90 | 13 | 41.5° |

| GDC6430-1220~1123 | 122.0~122.3 | 43 | 90 | 12 | 41° | |

| GDC6430-1220~1123-2 | 122.0~122.3 | 43 | 90 | 13 | 41° | |

| GDC6430-1220~1124 | 122.0~122.4 | 43 | 91 | 13 | 41.5° | |

| GDC6435-1221 | 122.1 | 43.5 | 90 | 12 | 41° | |

| GDC6435-1220~1228 | 122.0~122.8 | 43.5 | 90 | 13 | 41.5° | |

| Φ127 | GDC6435-1270~1275 | 127.0~127.5 | 43.5 | 95 | 13 | 41.5° |

| GDC6435-1270~1278 | 127.0~127.8 | 43.5 | 93 | 13 | 41° | |

| GDC6440-1270~1273 | 127.0~127.3 | 44 | 93 | 13 | 41.5° | |

| GDC6440-1270~1274 | 127.0~127.4 | 46 | 95 | 13.5 | 41.5° | |

| GDC6470-1270~1276 | 127.0~127.6 | 47 | 95 | 12 | 41.5° | |

| GDC6470-1270~1272 | 127.0~127.2 | 47 | 93 | 13 | 41.5° | |

| GDC6475-1275~1278 | 127.5~127.8 | 47.5 | 95 | 13 | 42° | |

| GDC6480-1270~1271 | 127.0~127.1 | 48 | 94 | 12.5 | 41.5° | |

| GDC6480-1270~1275 | 127.0~127.5 | 48 | 95 | 12 | 42.5° | |

| GDC6485-1271~1272 | 127.1~127.2 | 48.5 | 94 | 12 | 42° | |

| Φ128 | GDC6435-1221 | 128.0 | 41.5 | 93 | 12.5 | 41° |

| GDC6435-1221 | 128.0 | 46 | 96 | 13 | 41.5° | |

| GDC6460-1280~1282 | 128.0~128.2 | 46 | 93 | 13.5 | 41.5° | |

| Φ142 | GDC6490-1420 | 142.0 | 49 | 102 | 15 | 41.5° |

| Φ148 | GDC6570-1485 | 148.5 | 100 | 15 | 41° | |

| Φ160 | GDC6610-1600~1603 | 160.0~160.3 | 110 | 15 | 41.5° | |

| Φ175 | GDC6632-1753 | 175.32 | 63.25 | 102 | 15 | 41° |

Cemented carbide >>> Types, dimensions, and tolerances of sintered products

| Type | D | E | H | a | |||

| Nominal size | Tolerances allowed | Nominal size | Tolerances allowed | Nominal size | Tolerances allowed | 46° | |

| DC636 | 105.5 | +1.5 -0.5 |

35.6 | 0.5 | 76 | +1.5 -0.5 |

46° |

| DC643 | 116 | +1.7 -0.5 |

43 | 0.6 | 82.5 | +2.0 +0.5 |

46° |

| DC645-2 | 129 | +2.0 0 |

44.5 | 0.5 | 96 | +2.5 +0.5 |

46° |

| DC647-2 | 122 | +2.0 +0.7 |

47 | 0.5 | 90 | +2.0 +0.7 |

46° |

| DC648 | 129 | +3.6 +1.6 |

48 | 0.5 | 101 | +1.0 0 |

46° |

| DC648-6 | 129 | +2.0 0 |

47.5 | 0.5 | 96.4 | +1.0 0 |

46° |

| DC652 | 129 | +1.5 -0.5 |

52 | 0.5 | 93 | +2.0 +1.0 |

46° |

| DC661 | 160 | +2.5 +1.5 |

61 | 0.5 | 115 | +2.5 +1.5 |

46° |

| DC668 | 175 | +3.0 +1.2 |

67.4 | 0.5 | 92 | +3.3 +1.0 |

46° |

Cemented carbide >>> Grades, properties, and recommended applications of cemented carbide anvils and pressure cylinders

| Grade | Physical properties (typical value) | Recommended applications | |||

| Density g/cm |

HRA | HV3 HV |

TRS Mpa |

||

| YL10.3 | 14.95 | 90.5 | 1450 | 2300 | Special grade for 2-facet anvils |

| YL20.3 | 14.75 | 90 | 1400 | 3000 | Universal grade for 6-facet anvils with a higher hardness and TRS and the TRS will increase by 30% after the products are sintered at a low pressure. |

| YL20.4 | 14.75 | 90 | 1400 | 3200 | Special grade with a higher hardness and TRS and good resistance to thermal cracking for 6-facet anvils with a diameter over 160mm. |

| YL30.3 | 14.41 | 88.5 | 1250 | 3400 | For manufacturing pressure cylinders of the class of 30-50kgs |