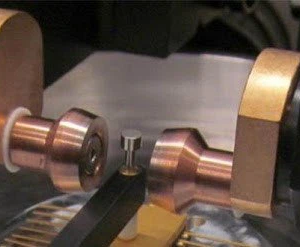

Copper Tungsten Electrode for Resistance Welding

Copper tungsten electrodes are widely used in resistance welding due to their exceptional thermal and electrical conductivity, high melting point, and resistance to erosion. The composition typically involves a blend of copper and tungsten, creating a material that combines the favorable attributes of both metals. These electrodes are known for their durability and ability to withstand the harsh conditions of resistance welding processes, ensuring prolonged service life and consistent performance in joining materials through the application of heat and pressure.

Applications of Copper Tungsten Composites

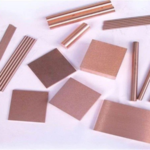

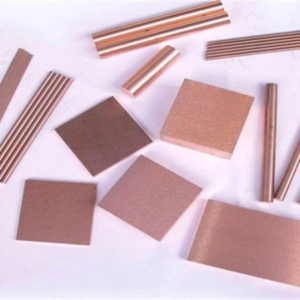

T&D composite materials, comprising tungsten or tungsten carbide and copper or silver, are produced through a precise manufacturing process. This involves pressing the refractory material (tungsten or tungsten carbide), sintering the compact at high temperatures, and subsequently infiltrating it with copper or silver, all conducted under stringent control conditions. The outcome is a durable material with excellent arc and wear resistance, impressive physical properties under elevated temperatures, and commendable electrical and thermal conductivity.

The composition influences the mechanical and physical characteristics, wherein the thermal and electrical conductivity rises with higher levels of copper and silver, while increased amounts of tungsten or tungsten carbide enhance hardness, strength, and resistance to mechanical wear. The choice of material depends on the specific application.

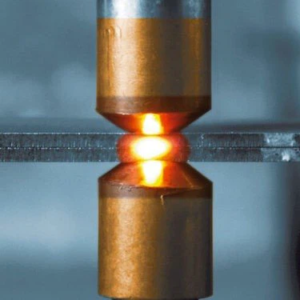

Resistance Welding

The excellent physical and mechanical characteristics, along with notable thermal and electrical conductivity, render refractory metal composites highly appropriate for applications such as die inserts and electrode facings, as well as for use in flash and butt welding dies and hot upsetting. Additionally, these materials can address challenges related to heat balance.

Heat Sinks

T&D Materials, Ltd developed Thermitech for widespread application in thermal mounting plates, chip carriers, flanges, and frames for high-power electronic devices. As a copper tungsten material, it’s a composite, that combines the thermal benefits of copper with the exceptionally low expansion properties of tungsten.

The combination of these two materials yields thermal expansion properties comparable to silicon carbide, aluminum oxide, and beryllium oxide, commonly employed in chips and substrates. Due to its effective thermal conductivity and expansion characteristics, it performs well in densely populated circuits.

Electrical Contacts

T&D Materials engineered Elecon materials for applications in oil-filled devices, air and gas circuit breakers, contactors, and high-voltage switchgear. Various typical uses include:

- Arcing contacts and plates

- Arc runners

- Current carrying members

- Blade facings

Our materials undergo a process of pressing, sintering, and infiltrating for production. Every manufacturing phase, from the initial powder to the final product, is meticulously controlled, monitored, and approved by our Quality Assurance team. Following production, each manufactured lot is thoroughly examined for conductivity, density, and hardness before shipment. Comprehensive records of this information are maintained and stored, and these records are also provided with the parts or materials upon request.

EDM and ECM

T&D Materials’ tungsten composites find global applications as electrodes in Electrical Discharge Machining (EDM) and Electrochemical Machining (ECM). The manufacturing process consists of pressing, sintering, and infiltrating, using virgin powders to ensure a consistently homogeneous material with high and uniform burning rates. Copper tungsten is specifically utilized in plunger/sinker applications that demand intricate definition, particularly in tungsten carbide.

Composites Typical Properties

| T & D Materials | RWMA Group B |

Nominal Composition % Weight |

Rockwell Hardness | Electrical Conductivity % IACS |

Ultimate Tensile Strength PSI |

Cross Breaking Strength PSI |

Density GMS/CC |

| H1W | 55% Tungsten 45% Copper |

79 B | 55 | 63,000 | 110,000 | 12.5 | |

| H3W | 68% Tungsten 32% Copper |

88 B | 52 | 75,000 | 130,000 | 13.93 | |

| H5W | 68% Tungsten 32% Copper |

88 B | 52 | 75,000 | 130,000 | 13.93 | |

| H15W | 70% Tungsten 30% Copper |

90 B | 50 | 85,000 | 140,000 | 14.18 | |

| H10W | Class 11 | 75% Tungsten 25% Copper |

94 B | 48 | 90,000 | 150,000 | 14.7 |

| H20W | Class 11 | 78% Tungsten 22% Copper |

96 B | 46 | 94,000 | 160,000 | 15.12 |

| H30W | 80% Tungsten 20% Copper |

98 B | 44 | 96,000 | 170,000 | 15.56 | |

| H10WA ** |

75% Tungsten 25% Copper Alloy ** Fully Heat Treated |

109 B | 28 | 96,000 | 170,000 | 15.56 | |

| H5TC | 50% Tungsten-Carbide 50% Copper |

94 B | 47 | 70,000 | 140,000 | 11.27 | |

| H10TC | 56% Tungsten-Carbide 44% Copper |

99 B | 42 | 75,000 | 160,000 | 11.67 | |

| H20TC | 70% Tungsten-Carbide3 0% Copper |

37 C | 30 | 85,000 | 180,000 | 12.6 | |

| HTCWA ** |

70% Tungsten-Carbide 30% Copper-Alloy ** Fully Heat Treated |

47 C | 18 | 150,000 | 220,000 | 12.6 | |

| H35S | 65% Tungsten 35% Silver |

87 B | 53 | 14.5 | |||

| H20S | 74% Tungsten 26% Silver |

90 B | 47 | 70,000 | 130,000 | 15.5 | |

| H50S | 50% Tungsten 50% Silver |

70 B | 65 | 35,000 | 80,000 | 13.4 | |

| HG-13 | 50% Tungsten Carbide 50% Silver |

79 B | 47 | 40,000 | 115,000 | 12.2 | |

| HG-14 | 60% Tungsten Carbide 40% Silver |

95 B | 40 | 55,000 | 120,000 | 12.8 | |

| HG-17 | 60% Molybdenum 40% Silver |

80 B | 47 | 10.2 |

Need a Custom Project?

Phone

Address

Phone

Related products

-

Tungsten Copper Alloy

Copper Tungsten Electrodes in Electric Spark Erosion Cutting Machines

Read more