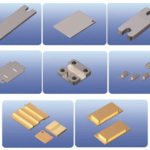

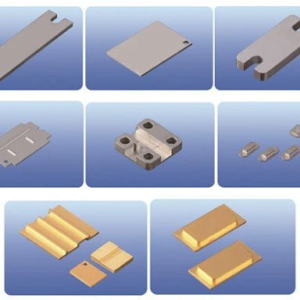

Copper Molybdenum Parts

Molybdenum Copper alloy combines Molybdenum and Copper to create a composite material with performance characteristics similar to Tungsten Copper alloy. However, its density is lower than that of Tungsten Copper alloy, making it particularly well-suited for applications in the aerospace and navigation industries.

Over the years, T&D has consistently delivered cutting-edge hermetic connector and packaging technologies to customers. This includes a controllable expansion composite matrix that ensures superior material stability and uniform thermal expansion characteristics. This provides designers with a practical solution to meet critical thermal parameters.

Advantages of Molybdenum Copper (MoCu):

- Design options for thermal expansion

- Excellent thermal conductivity

- Precision flatness capabilities

- Gold plating suitable for bonding

- Thickness ranging from .004″ to .500″

- Sharp corner radius

- Integrated ribs for added strength

- Precision complex geometry

- Minimal thermal expansion

- Favorable electrical conductivity

- Superior wear resistance

- Lighter compared to W-Cu

Typical Physical and Mechanical Properties:

| Material Composition | Density (g/cm3) | Thermal Conductivity W/moK 25°C | Coefficient of Thermal Expansion 10-6/°C |

| 85Mo/15Cu | 10.01 | 195 | 7.0 |

| 80Mo/20Cu | 9.96 | 204 | 7.6 |

| 70Mo/30Cu | 9.75 | 208 | 8.0 |

| 60Mo/40Cu | 9.62 | 223 | 9.3 |

| 50Mo/50Cu | 9.51 | 230 | 10.3 |

Common Application Areas:

- Heat Sinks and Spreaders

- Microwave Carriers

- Microelectronic Package Bases and Housings

- Ceramic Substrate Carriers

- GaAs and Silicon Device Mounts

- Laser Diode Mounts

- Surface Mount Package Conductors

- Microprocessor Lids

- Rocket Parts

- Optical Packages

- Power Packages

- Butterfly Packages