Rhenium Tungsten Anode in X-Ray Tube

Rhenium Tungsten Anodes in X-ray tubes represent an advanced and durable technology utilized in medical imaging and industrial applications. Composed of a tungsten target with a rhenium alloy, this anode offers enhanced heat resistance and stability, enabling prolonged exposure to high temperatures during X-ray generation. The combination of tungsten and rhenium results in improved performance, allowing for higher tube currents and more efficient X-ray production, ultimately contributing to clearer and more detailed radiographic images in medical diagnostics and non-destructive testing.

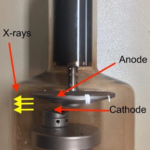

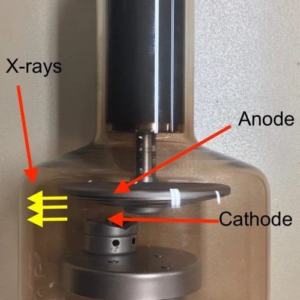

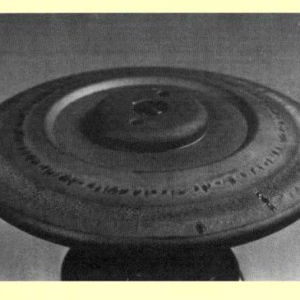

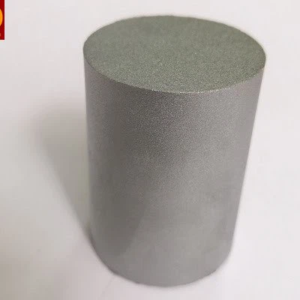

The anode, also known as the anticathode, serves as the component in X-ray tubes responsible for generating X-rays. Comprising a metal piece shaped like a disk with a diameter ranging from 55 to 100mm and a thickness of 7mm, it is connected to the positive side of the electrical circuit. The anode transforms the energy of incoming electrons into X-rays, releasing heat as a byproduct.

X-ray tube anodes typically utilize tungsten as the primary material. Tungsten, characterized by a high atomic number (Z=74) and an impressive melting point of 3370°C, exhibits a low rate of evaporation. This high atomic number enhances production efficiency compared to materials with lower atomic numbers. Additionally, an alloy incorporating tungsten and rhenium is employed to prevent surface grazing, with 5-10% rhenium serving this purpose. The anode body is crafted from lightweight materials with excellent heat storage capacity, such as molybdenum and graphite. Molybdenum, with an intermediate atomic number (Z=42), is often chosen as the target material for mammography anodes, producing X-rays tailored for this application. Rhenium (Z=45) is also utilized in some mammography anodes, generating characteristic X-rays with slightly higher energies that are more penetrating and preferable for dense breast imaging.

The anode disc undergoes rotation and encounters a focused beam of electrons emitted from the cathode, accelerated by a substantial potential difference between the cathode and the anode. When the electron beam hits the anode at the designated focal spot, interactions between the electrons and the target material generate the X-ray beam. The anode angle, typically ranging from 12-15° in most X-ray tubes, represents the angle between the vertical axis and the target surface. A reduced angle leads to a smaller effective focal spot.