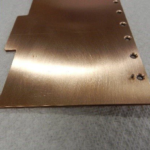

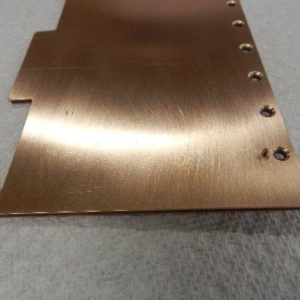

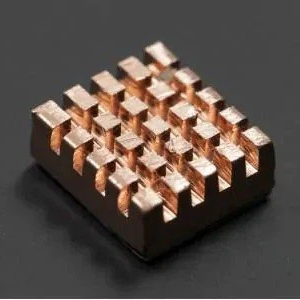

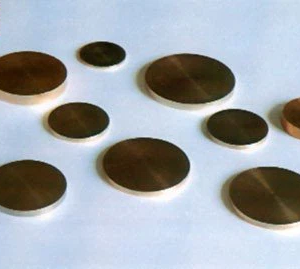

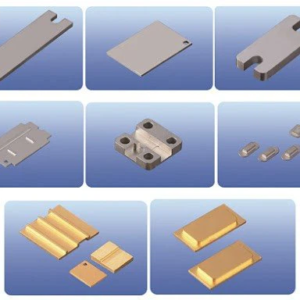

Copper Molybdenum Heat Sinks

Copper molybdenum heat sinks are thermal management devices designed to efficiently dissipate heat generated by electronic components. These heat sinks typically consist of a base made of copper for excellent thermal conductivity and a top layer of molybdenum for enhanced durability and resistance to high temperatures. The combination of these materials allows for effective heat transfer and dissipation, making copper molybdenum heat sinks ideal for applications in electronic devices such as computer processors and power electronics where heat management is crucial for optimal performance and reliability.

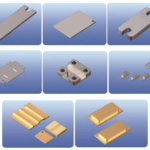

Molybdenum copper alloy is a blend of molybdenum and copper, offering an adjustable thermal expansion coefficient and thermal conductivity. With a lower density than tungsten copper, molybdenum copper alloy is a more fitting choice for aerospace and various other applications.

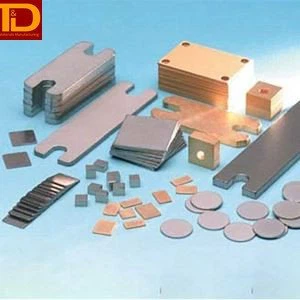

Advantages:

- These molybdenum copper base plates exhibit exceptional hermeticity along with high thermal conductivity.

- Molybdenum copper flanges are 40% lighter than equivalent tungsten copper composites.

Product Properties:

| Grade | Mo Content | Density g/cm3 | Coefficient of thermal

Expansion ×10-6 (20℃) |

Thermal conductivity W/(M·K) |

| 70MoCu | 70±2% | 9.8 | 7 | 200 (25℃) / 196 (100℃) |

| 60MoCu | 60±2% | 9.66 | 7.5 | 222 (25℃) / 217 (100℃) |

| 50MoCu | 50±2% | 9.5 | 10.2 | 250 (25℃) / 220 (100℃) |

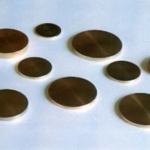

Application:

Molybdenum copper heat spreaders are widely used in various applications, including microwave carriers, ceramic substrate carriers, laser diode mounts, optical packages, power packages, butterfly packages, and crystal carriers for solid-state lasers, among others.