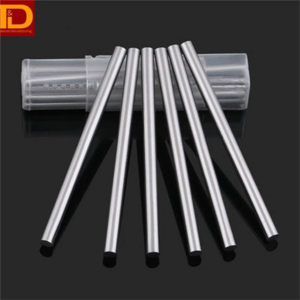

Tungsten Heavy Metal Boring Bar

Tungsten heavy metal boring bars are manufactured with alloys of 90% – 97% tungsten. Their surface can be either a sintered form, machined form, or polished form.

Tungsten heavy metal boring bars have similar properties to tungsten carbide boring bars, but the different chemical compositions can help to reduce brittle. The high density and tensile strength of tungsten heavy metal boring bars allow them to be great at resisting the chatter. It also has the name chatter-free boring bar or super chatter-free boring bar.

Tungsten heavy metal boring bars are widely used for boring bars, grinding mandrels, tool shafts, and types of precision tools that need vibration damping to ensure smooth running.

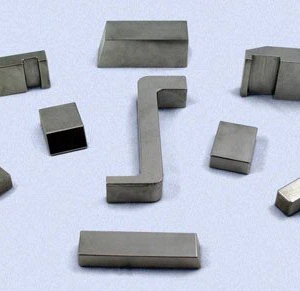

Tungsten Heavy Metal Tool Holder

Tungsten heavy metal tool holders are manufactured with alloys of 90% – 97% tungsten. Their surface can be either a sintered form, machined form, or polished form.

Whether you are riveting, drilling, grinding, or lathing: machining lightweight, soft materials can often result in oscillations, vibrations, or loud noise emissions.

The combined high density, high elastic (Young’s) modulus, and machinability of tungsten heavy metal tool holder make it a great material for chatter-free boring bars and grinding quills.

T&D has standard sizes of heavy material bars and solid carbide bars in stock at our Clifton Heights, PA warehouse.

We can supply you rough turned with 0.020” / 0.060” stock, ensuring optimal straightness.

We can also supply you with centerless finished rods with the following tolerance:

1/8” dia – 7/8” dia, the tolerance of diameter is +0” / -0.0005”

1.00” dia – 3.00” dia, the tolerance of diameter is +0” / -0.001”

The length tolerance is +/- 0.010”

All lengths between 1” and 20” are available.

Our standard lengths are: 4”, 4.5”, 6.0”, 8”, 10”, 12”, 16”, 18”, 20”

Our standard diameter sizes are: 1/8”, 3/16”, 1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 7/8”, 1.0”, 1 1/8”, 1 1/4”, 1 3/8”, 1 1/2”, 1 5/8”, 1 3/4”, 2.0”, 2.5”, 3.0”

High Density Tungsten Alloys Material (Heavy Metal)

We make our heavy metals as per ASTM B777- 87. The density can be 17.0g/cc, 17.7g/cc, 18.0g/cc, and 18.50g/cc. Most boring bar makers need 17g/cc and 17.7g/cc materials.

90% W

- Density: 17 g/cc

- Hardness: > 24 HRC

- Ultimate Tensile Strength: > 110,000 psi

- Yield Strength. 2% offset: > 90,000 psi

- Elongation: > 8%

93% W

- Density: 17.7 g/cc

- Hardness: > 30 HRC

- Ultimate Tensile Strength: > 130,000 psi

- Yield Strength. 2% offset: > 90,000 psi

- Elongation: > 10%

97% W

- Density: 18.50 g/cc

- Hardness: > 28 HRC

- Ultimate Tensile Strength: > 125,000 psi

- Yield Strength 2% offset: > 85,000 psi

- Elongation: > 10%

- Solid Carbide Material (Tungsten Carbide)

- ISO k20, k30 (YL 10.20 grade) – other grades are available.

- Cobalt Content: 10%

- Grain Size: 0.80um

- Density: 14.42 g/cc

- Hardness: 91.80 HRA

- TRS: 4000 N/sq mm

T&D is an ISO9001:2015 certified domestic supplier of Tungsten Carbide, Heavy Tungsten Alloy, Copper Tungsten, Tungsten, Molybdenum, Tantalum, and Niobium either semifinished blanks or as precision-machined parts. We can deliver your order machined to meet your specifications based on your technical drawings. Our services are available for prototyping and low-to-high-volume production runs.

Modern equipment, low costs, and short lead times allow T&D Materials Manufacturing to provide its customers with quality products and excellent customer service. Our capabilities include direct pressing and MIM, CNC pre-forming, HIP sintering to assure consistently high strength, and fully automated CNC finishing to close tolerances and superior finishes.

All our tungsten and tantalum raw materials come from ”Conflict-Free” sources.

ITAR Compliant

T&D Materials Manufacturing Produces all products meeting industry standards of ISO, ASTM, ASM, and MIL as well as custom grades.