Heavy Tungsten Alloy Bucking Bar

Tungsten alloy bucking bars are essential tools in metalworking, offering unparalleled durability and effectiveness in riveting and shaping operations. As a key component in aerospace and automotive industries, the tungsten bucking bar is known for its high-density composition, providing superior resistance to wear and deformation. These bucking bars ensure precise and efficient rivet placement, making them indispensable for professionals seeking reliability in their metal fabrication processes. Explore the advantages of tungsten bucking bars for a resilient and efficient solution in your bucking bar needs.

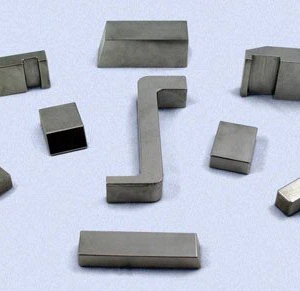

Tungsten Bucking Bars for Riveting

Tungsten alloy bucking bars serve as a work tool positioned behind work surfaces to act as a supporting element when applying impact fasteners. It consists of intermittent tool head and handle components, with a low-recoil impact-absorbing spacer between them, designed to absorb shock loads in both compression and shear. Tungsten alloy bucking bars are employed on the backside of a metal rivet to counteract the force generated by hammering on the opposite side. They can also absorb the force of rivet guns, thereby decreasing the bucking vibration. Employed in riveting applications to upset the shank of the rivet, the tungsten alloy bucking bar diminishes recoil while transmitting impact to the rivet shaft.

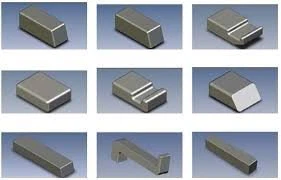

Tungsten alloy bucking bars are utilized to shape bucktails on rivets and are available in various shapes and sizes. Typically made from steel alloys akin to tool steel, the specific shape chosen depends on the location and accessibility of the rivet to be installed. The dimensions and weight of the bar are contingent upon the size and alloy of the rivet intended for installation. In specific cases and for particular rivet setups, custom-designed bucking bars are manufactured locally. Bucking bars from T&D are typically made using tungsten heavy alloy. The edges are all deburred, and the working surfaces are polished and non-porous to optimize their functionality. This aids in preventing marring on the bucktails.

Experience enhanced and more efficient riveting with reduced fatigue. Tungsten alloy bucking bars provide the highest density possible, being over twice as heavy as an equivalent steel bar. Their compact size and exceptional density make these bars versatile, enabling them to fit into small spaces. For safety and ease of handling, all bars feature a complete radius on every edge.

Research indicates that tungsten alloy bucking bars with identical shapes but composed of different materials exhibit different properties. More massive bars can minimize the transmission of vibrations to the hand. Increased density lessens vibration and recoil during bucking. The use of a tungsten alloy bucking bar can significantly simplify any riveting process. Follow the example of professionals and opt for the tools they prefer. Our selection includes a comprehensive range of standard bars. We can also custom-manufacture bars to your specifications. All bars feature smooth faces and rounded edges and corners, for ease and safety in handling.