Tungsten Alloy Barrel Weight Shape

The tungsten alloy barrel weight forms the main part of a dart. When we are speaking of “buying a (new) dart” we mean getting a new dart barrel. Nowadays tungsten alloy barrel weight are available in almost every possible shape, with a wide selection of knurl or rings on the surface for a comfortable and safe grip. The main tungsten alloy barrel weight shapes are CYLINDER, TON, and TORPEDO.

It’s not possible to say which one is the “right” one. Based on a very theoretical reasoning the long cylindrical barrel could be the best of them because it is the slimmest and allows the tightest grouping. Good for 140s and 180s. But this reasoning doesn’t help you when you are not able to handle such a tungsten alloy barrel. Selecting the right shape is a matter of personal preference. Choose what feels comfortable for you. This is much more important than an abstract or “academic” reasoning about theoretical advantages or disadvantages of some shapes.

Tungsten Alloy Barrel Surface

The surface of tungsten alloy barrel is covered by knurling or rings for a safe grip on the dart. Again there is a vast selection of different surface shapes, and combinations of them. And there is the possibility of a plain surface (which beginners are usually unhappy with). Again, it can’t be said which variations are the best ones. Choose what suits you, what feels good

There is only one thing you should avoid: painted surfaces. Paint might look good, but usually it makes the dart only more slippery. The probably only exception here is Unicorn’s “gold” brand. These darts are covered with a golden coat (I don’t know what material this coating is. But it’s not gold) which they say improves the grip.

Tungsten Alloy Barrel Weight

Dart weight is a never ending story. A lot of people want to know which weight they should throw, which weight is the most common one, what’s the average weight and so on. In my mind, tungsten alloy barrel weight is the best material. For the “average weight” question there probably is an answer, but it doesn’t make much sense.

If you ask the average question now the answer will be 20 grams, but does this make sense when the weights vary that much?

For a beginner steel dart player I recommend a tungsten alloy barrel weight between 22 and 25 grams. Tungsten alloy barrel weight is slightly on the heavy side. The reason is that you need to develop a basic throwing skill in order to reach a certain initial level of play with darts on the heavy side. You would probably reach such a level a bit faster with lighter darts, but lighter darts don’t force you to develop a somehow decent technique which will make later improvement a lot harder. Heavier darts also forgive slight technical inconsistencies (in other words: errors) better than lighter darts — I like to tell heavier darts more “good-natured” because of this. The lighter the dart the more sensible it reacts to what you are doing — slight intentional adjustments as well as slight technical errors or deficits.

Once you have got some darting experience and a decent technique you may find the heavier dart not that convincing any longer because of its good-natured behavior. If you then think you could use a dart that reacts more sensible you should consider going lighter.

Soft tip players won’t have that much of a choice for their tungsten alloy barral weight. The limit set by the machine operators and leagues usually is below 20 grams. If you are a beginner in soft tip the only advice I can give you concerning the weight of your darts is start at the maximum allowed weight.

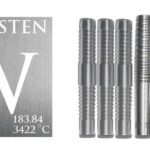

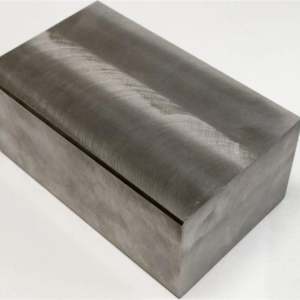

Tungsten Alloy Barrel Weight Material

Today’s standard material is Nickel-Tungsten. Tungsten is a very dense material, so darts with a considerable weight can be made quite slim. The tungsten alloy barrel weight had a big impact on the sport. With the new darts it was possible to achieve much better grouping than before, and the averages in pro games have improved dramatically. It is not an overstatement when this development is referred to as “the tungsten revolution”. were mainly made of brass. Brass darts are still used by some players because they are much cheaper than Tungsten. But brass darts are ancient technology now, so I can’t recommend them.

is not available. All “tungsten” darts you can buy are in fact made of tungsten alloys, with Nickel-Tungsten being the most common one. When you buy a dart the amount of tungsten in the alloy is given by a percentage number. So a common “80% Tungsten” dart has 80 percent tungsten and 20 percent Nickel, Copper and/or Ferro. Tungsten darts are available from 80% to over 90%. The more tungsten the slimmer – and the more expensive – the dart is. If the high-percentage tungsten darts are worth the higher price is an open question. Personally I think that 80% tungsten are good enough for almost everyone.

Remember: the only benefit from a high tungsten alloy barrel weight share is that the dart can be made slimmer than a dart with the same weight and a lower tungsten share. In no way do higher tungsten percentages indicate some sort of overall better quality or better machining.

In recent years a growing number of people has become allergic to Nickel. With Nickel-Tungsten darts being the standard equipment nowadays these people will have problems with their darts. There are a few darts available with different tungsten alloys, such as silver tungsten or copper tungsten. However, these darts are very rare. The major dart manufacturers don’t supply them. If you are allergic to Nickel you will probably have to look for these alternatives.

Tungsten Alloy Barrel Sizes

| Tungsten Alloy Billet Size [Ø(+0.05)×(+1.0)mm] |

Content of W (%) | |||||||

| 65 | 70 | 80 | 85 | 90 | 95 | |||

| Density (+/-0.25g/cc) | ||||||||

| 13.20 | 13.90 | 15.40 | 16.00 | 16.90 | 18.00 | |||

| No. | inch | mm | Weight (+/-0.50g/pc) | |||||

| 1 | Ø1/4×1.7 | Ø6.35×43.2 | ||||||

| 2 | Ø1/4×1.8 | Ø6.35×45.7 | ||||||

| 3 | Ø1/4×1.9 | Ø6.35×48.3 | ||||||

| 4 | Ø1/4×2.00 | Ø6.35×50.8 | ||||||

| 5 | Ø1/4×2.15 | Ø6.35×54.6 | ||||||

| 6 | Ø0.265×1.7 | Ø6.73×43.2 | ||||||

| 7 | Ø0.265×1.8 | Ø6.73×45.7 | ||||||

| 8 | Ø0.265×1.9 | Ø6.73×48.3 | ||||||

| 9 | Ø0.265×2.00 | Ø6.73×50.8 | ||||||

| 10 | Ø0.265×2.15 | Ø6.73×54.6 | ||||||

| 11 | Ø9/32×1.6 | Ø7.15×40.7 | ||||||

| 12 | Ø9/32×1.7 | Ø7.15×43.2 | ||||||

| 13 | Ø9/32×1.8 | Ø7.15×45.7 | ||||||

| 14 | Ø9/32×1.9 | Ø7.15×48.3 | ||||||

| 15 | Ø9/32×2.00 | Ø7.15×50.8 | ||||||

| 16 | Ø9/32×2.15 | Ø7.15×54.6 | ||||||

| 17 | Ø5/16×1.6 | Ø7.94×40.7 | ||||||

| 18 | Ø5/16×1.7 | Ø7.94×43.2 | ||||||

| 19 | Ø5/16×1.8 | Ø7.94×45.7 | ||||||

| 20 | Ø5/16×1.9 | Ø7.94×48.3 | ||||||

| 21 | Ø5/16×2.00 | Ø7.94×50.8 | ||||||

| 22 | Ø11/32×1.4 | Ø8.74×35.6 | ||||||

| 23 | Ø11/32×1.6 | Ø8.74×40.7 | ||||||

| 24 | Ø11/32×1.8 | Ø8.74×45.7 | ||||||

| 25 | Ø11/32×2.00 | Ø8.74×50.8 | ||||||