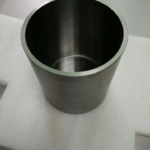

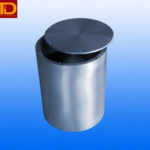

- The following crucible sizes are available: 30kg, 35kg, 55kg, 65kg, 90kg, 120kg.

- The purity is 99.95% min for both tungsten crucibles and molybdenum crucibles.

- Particularly high density.

- We have equipment to test physical properties such as density, hardness, surface roughness, grain size, tensile strength, etc. The possible internal injuries of the crucible such as porosity, slag, and cracks are strictly inspected by eddy current and ultrasound.

- We mostly supply forging crucibles with a high density. Machined from deep forged tungsten rods, their density is very close to the theory value. For some extremely large outside-diameter crucibles, we supply sintering finished crucibles. We still get good density controlling the HIP furnace sintering temperature.

- All our crucibles can be used for above 2000ºC.

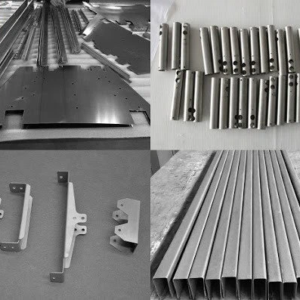

- We can also make a complete hot zone for a sapphire crystal growth furnace; tungsten heater; molybdenum up shields, side shields; tungsten down shield, base shield; molybdenum current lead shields, current lead shield; tungsten stander, supporter, and tungsten crucible pallet; molybdenum bottom; tungsten and molybdenum see holder etc.

- Creep resistance, corrosion resistance.

- Machined finished inside and outside with good surface roughness.

- All outside, height, wall thickness, and base thickness are available.

- All other tungsten/molybdenum accessories are available.

T&D is an ISO9001:2015 certified domestic supplier of Tungsten Carbide, Heavy Tungsten Alloy, Copper Tungsten, Tungsten, Molybdenum, Tantalum, and Niobium either semifinished blanks or as precision-machined parts. We can deliver your order machined to your specifications as per your drawings. Services available for prototyping and low-to-high volume production runs.

Modern equipment, low costs, and short lead times allow T&D Materials Manufacturing to provide its customers with quality products and excellent customer service. Our capabilities include direct pressing and MIM, CNC pre-forming, HIP sintering to assure consistently high strength, and fully automated CNC finishing to close tolerances and superior finishes.

All our tungsten and tantalum raw materials come from ”Conflict-Free” sources.

ITAR Compliant

T&D Materials Manufacturing Produces all products meeting industry standards of ISO, ASTM, ASM, and MIL as well as custom grades.

Purchasing options include blanket orders, just-in-time delivery, and consignment materials. If you are looking for high-quality W/Mo/Ta/Nb/WC/WCu/Re products, contact us today at 484-472-6863 or info@TDmfginc.com.