Molybdenum Evaporation Boats

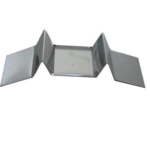

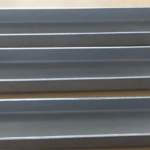

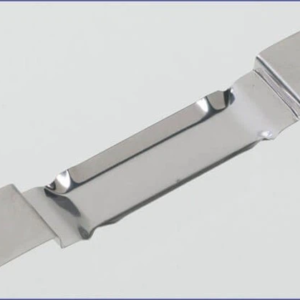

Evaporation Boats are capable of depositing a wide variety of materials. T&D offers an extensive selection of molybdenum boats, tantalum boats, standard tungsten boats, and custom fabrication to meet your specific evaporation source needs. All of our evaporation boats are available in a variety of materials and thicknesses. If you need help selecting the right boat for your process, please give our technical staff a call.

Molybdenum is a particularly stable metal that is also suitable for use at high temperatures. When doped with lanthanum oxide (ML), molybdenum becomes even more ductile and corrosion-resistant. The addition of yttrium oxide (MY) improves the material’s machinability.

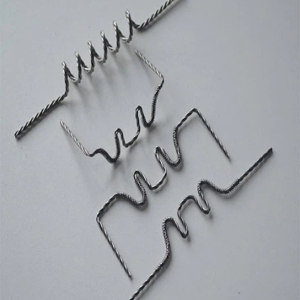

We supply crucible inserts manufactured from molybdenum, tungsten, and tantalum for use in electron beam evaporation. We would be happy to optimize the geometry and material composition of our crucibles for use in your coating process. Our tungsten and molybdenum coils are used in electrical resistance evaporation.

Thermal vacuum evaporation (resistance evaporation) is a coating method used as part of the PVD process (Physical Vapor Deposition). The material that is to form the subsequent layer is heated in a vacuum chamber until it evaporates.

In the vacuum evaporation process, resistant layers are produced, for example, from aluminum, silver, chromium, titanium nitride, or silica. This results in gleaming watches, flawless mirrors, and top-quality electronic components. You can be assured of long service lives and a high level of dimensional accuracy. Benefiting from our extensive experience, we have the expertise to optimize the material and geometries of our evaporation boats to perfectly align with your specific process requirements. Our team would be more than happy to advise you in selecting the right boat for your process.

The materials can be Molybdenum, Tungsten, TZM Molybdenum and Tantalum.

|

|

|

||

| BS-1 | BS-2 | BS-3 | ||

|

|

|

||

| BS-4 | BS-5 | BS-6 | ||

|

|

|

||

| BS-7 | BS-9 | BS-10 | ||

|

|

|

||

| BS-11 | BS-12 | BS-13 | ||

|

|

|

||

| BS-14 | BS-16 | BS-17 | ||

|

|

|

||

| BS-18 | BS-19 | BS-20 | ||

|

|

|

||

| BS-21 | BS-22 | BS-23 | ||

|

|

|

||

| BS-24 | BS-26

Covers with holes are available |

BS-28 | ||

|

|

|

||

| BS-29 | BS-31 | BS-32 | ||

|

|

|

||

| BS-33 | BS-34 | BS-35 | ||

|

|

|

||

| BS-38 | BS-39 | BS-41 | ||

|

|

|

||

| BS-40 | BS-42 | BS-43 | ||

|

|

|

||

| BS-44 | BS-45 | BS-46 | ||

|

|

|

||

| BS-47 | BS-48 | BS-49 | ||

|

|

|

||

| BS-52 | BS-53 | BS-54 | ||

|

|

|

||

| BS-55 | BS-56 | BS-57 | ||

|

|

|

||

| BS-58 | BS-59 | BS-60 | ||

|

|

|

||

| BS-62 | BS-63 | BS-64 | ||

|

|

|

||

| BS-65 | BS-67 | BS-68 | ||

|

|

|

||

| BS-69 | BS-71 | BS-72 | ||

|

|

|

||

| BS-74 | BS-75 | BS-76 | ||

|

|

|

||

| BS-78 | BS-79 | BS-86 | ||

|

|

|

||

| BS-97 | BS-98 | BS-99 | ||

|

||||

| BSF-1 | ||||