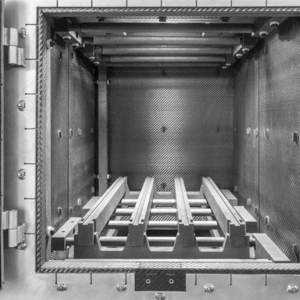

Molybdenum Hot Zones

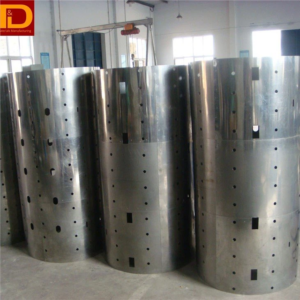

T&D supplies high-quality Tungsten, Molybdenum, Tantalum, and Niobium products for the furnace industry including Hot Zones, HIP Cylinders, Rotary Tubes, Heating Elements, Charge Carries, Shielding, Formed Crucibles, Pressed Crucibles, Annealing and Sintering Boats, screws, rivets, bolts, sheets, rods, wire, plates, tubes…

T&D supplies high-quality Tungsten, Molybdenum, Tantalum, and Niobium products for the furnace industry including Hot Zones, HIP Cylinders, Rotary Tubes, Heating Elements, Charge Carries, Shielding, Formed Crucibles, Pressed Crucibles, Annealing and Sintering Boats, screws, rivets, bolts, sheets, rods, wire, plates, tubes…

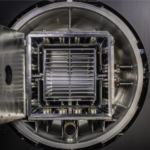

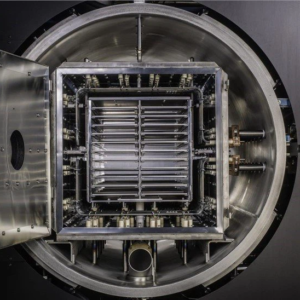

High-vacuum annealing and brazing impose exacting demands on the purity and cleanliness of the furnace, temperature uniformity, and the capability of achieving rapid cooling.

Depending on the operating conditions and the products to be processed, metallic hot-zones and charge carriers made of molybdenum and tungsten are used.

- Vacuum brazing for applications in aerospace (brazing repair of turbine blades, brazing of honeycombs)

- Outgassing and clean annealing in electronics and medical technology

- Production of vacuum switches for power engineering

- Laboratory, production, and special furnaces in development departments and in materials research

We supply the following:

- Development, design, and manufacture of complete hot zones for vacuum furnaces

- Replacement, rebuilding, and upgrading of hot zones of existing vacuum furnaces (also replacing graphite hot zones with metallic hot zones)

- Heating elements, charge carriers, and furnace boats for pusher furnaces

- Component manufacturing (heating elements, radiation shields, charge carriers, and accessories)

- Spare parts and semi-finished products (plates, sheets, wires, rods, and fasteners)