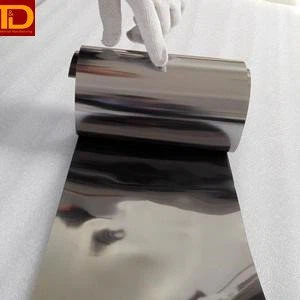

Molybdenum Foil

Materials below .005 inches in thickness are classified as foil. Typical uses for foils are producing drawn parts, electronic components, metalizing sources, furnace insulation, and chemically etched parts. Molybdenum foil can be etched into fine patterns, which makes it useful to the semiconductor industry. Standard availability is described below. Other sizes and tolerances are available and can be quoted upon request.

| Thickness | Max. Width |

| .001″ – .002″ | 12″ |

| .002″ – .003″ | 12″ |

| .003″ – .005″ | 12″ |

Molybdenum Foil Standard Thickness Tolerance

| Thickness | .25″ to 12″ |

| .001″ – .005″ | ± .0002″ |

Molybdenum Foil Standard Width Tolerance

| Thickness | .25″ to 6″ | 6″ to 12″ |

| .001″ – .004″ | ± .008″ | ± .012″ |

| .004″ – .005″ | ± .010″ | ± .015″ |

Surface Condition

Surfaces can be supplied in a mirror or matte finish; depending on thickness and width parameters.

Heat Treatment

Molybdenum flat products are rolled and annealed to provide the optimum condition for the desired end use (Furnace, Punch, Deep Draw).

MOLYBDENUM SHEET

Materials from .005 inches to .090 inches in thickness are classified as a sheet. Sheets are used for the fabrication of sintering boats, high-temperature furnace heating elements, and heat shields. Standard availability is described below. Other sizes and tolerances are available and can be quoted upon request.

| Thickness | Max. Width |

| .005″ to .015″ | 24″ |

| > .015″ to .040″ | 24″ |

| > .040″ to .090″ | 24″ |

Molybdenum Sheet Standard Thickness Tolerance

| Thickness | .25″ to 6″ | 6″ to 12″ | 12″ to 24″ |

| .005″ – .009″ | ± .0005″ | ± .0005″ | ± .002″ |

| .009″ – .015″ | ± .0008″ | ± .0009″ | ± 10% |

| .015″ – .020″ | ± .0010″ | ± .0010″ | ± 10% |

| .020″ – .040″ | ± .0015″ | ± .0015″ | ± 10% |

| .040″ – .050″ | ± .003″ | ± .003″ | ± 10% |

| .050″ – .065″ | ± .004″ | ± .004″ | ± .004″ |

| .065″ – .090″ | ± .005″ | ± .005″ | ± .005″ |

Molybdenum Sheet Standard Width Tolerance

| Thickness | .25″ to 6″ | 6″ to 12″ | 12″ to 24″ |

| .005″ – .009″ | ± .012″ | ± .015″ | ± .025″ |

| .009″ – .015″ | ± .012″ | ± .015″ | ± .025″ |

| .015″ – .020″ | ± .012″ | ± .020″ | ± .025″ |

| .020″ – .040″ | ± .020″ | ± .030″ | ± .030″ |

| .040″ – .050″ | ± .020″ | ± .030″ | ± .030″ |

| .050″ – .065″ | ± .020″ | ± .030″ | ± .030″ |

| .065″ – .090″ | ± .030″ | ± .031″ | ± .031″ |

Surface Condition

Surfaces can be supplied in a shiny, matte, satin, or as-rolled condition; dependent upon thickness and width parameters.

Heat Treatment

Molybdenum flat products are rolled and annealed to provide the optimum condition for the desired end use (Furnace, Punch, Deep Draw).