Molybdenum heat shields are very similar to the nature of the molybdenum and tungsten in its boiling point and electrical properties. compared with tungsten, the ease of processing linear thermal expansion coefficient is small.

Metal molybdenum thermal conductivity of 135 W / (m · open) and specific heat of 0.276 kJ / (kg · open)] was the best match, making it the best choice for thermal shock and thermal fatigue. Its melting point is 2620 ℃, inferior to tungsten, tantalum, but the density was compared with a much lower specific strength (strength/density) is greater than metals such as tungsten, tantalum, weight very critical applications, is valid. Molybdenum at 1200 ° C is still high strength.

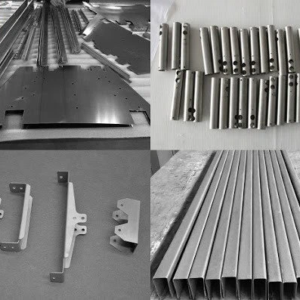

Molybdenum heat shield has the following characteristics: linear thermal expansion coefficient is small, easy to process, low thermal conductivity, and small specific heat.

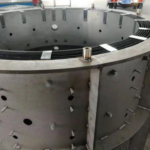

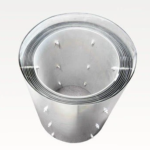

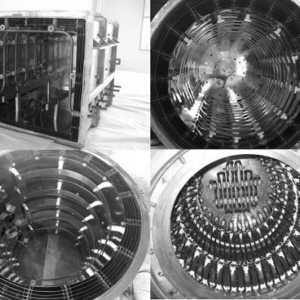

Standard vacuum furnace in a 1315 °C operating temperature, the heat shields are two layers of molybdenum sheet, outside the three-tier stainless steel sheet within the composition. If you require a higher operating temperature, the number of layers of molybdenum sheet thickness of each layer should be increased. If temperatures exceed 1650 °C, a tantalum sheet can be used to replace the molybdenum sheet. Full Metal heat insulation performance is good or bad depending on the layers and the spacing between the sheet metal, these intervals is used to prevent heat conduction radiating outward from the center area of the thermal field. Due to the reflective properties of the molybdenum sheet, the thermal radiation re-reflection to the workpiece at the center of the thermal field issued from the central area of the thermal field. The all-metal thermal field are often applicable to the use of the environment of high vacuum and cleanliness requirements. For Full Metal heat should be noted that the molybdenum metal above 1150 ℃, due to the recrystallization of the metal will produce embrittlement, embrittlement of the metal heat shield vulnerable to fall onto the screen above the fixture or workpiece damage. Due to higher molybdenum prices, the cost of the all-metal thermal field also tends to be higher than the thermal field made of other materials.