The molybdenum sputtering target has the same properties as its raw material. In its pure form, molybdenum is a silvery-grey metal with a Mohs hardness of 5.5 and a standard atomic weight of 95.95 g/mol. It has a melting point of 2,623 °C (4,753 °F); of the naturally occurring elements, only tantalum, osmium, rhenium, tungsten, and carbon have higher melting points. It has one of the lowest coefficients of thermal expansion among commercially used metals.

Molybdenum has the advantages of superior electrical and thermal conductivity, small thermal expansion coefficient, and strong corrosion resistance. It is mainly used in electric vacuum devices, high temperature furnace heating elements, heat insulation boards, evaporation boats, etc. For molybdenum sputtering targets, it’s widely used for fields of TFT-LCD, thin film solar cells, and semiconductor fields.

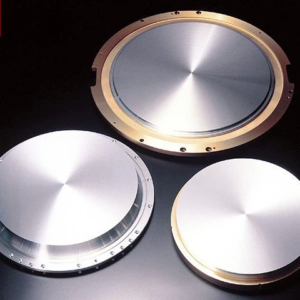

Thanks to our special forming processes, our Molybdenum sputtering targets possess higher density and smaller average particle size, so you can benefit from a faster process due to higher sputtering speed.

The microstructure can be adjusted by our flexible production process, to achieve your desired effect. If the grains of the sputtering target are uniformly aligned, the user can benefit from constant erosion rates and homogeneous layers. Following are two micrographs of our molybdenum sputtering target, with an average grain size of <100μm.

The chemical purity is crucial to a metal sputtering target, if the purity is higher, the films will possess a more outstanding level of electrical conductivity and minimized particle formation during the PVD process. Following is a typical Certificate of analysis for the 3N5 Molybdenum sputtering target.

Molybdenum sputtering target preparation process

Material Preparation-Sintering-Chemical Analysis-Rolling-Annealing-Metallographic Inspection-Machining-Dimensional Inspection-Cleaning-Final Inspection-Packaging-Shipment

Manufacturing method of molybdenum sputtering target

Molybdenum powder is provided; the molybdenum powder is densified for the first time by a static pressing process to form the first molybdenum target blank; the first molybdenum target blank is placed in the sheath and vacuumed; the package is compressed by a cold isostatic pressing process The first molybdenum target blank in the sleeve is subjected to a second densification treatment to form a second molybdenum target blank; after the second densification treatment, the sheath is removed, and the second molybdenum target blank is subjected to the second molybdenum target blank by an induction sintering process After the third densification treatment, the third molybdenum target blank is formed; after the third densification treatment, the third molybdenum target blank is rolled by the hot rolling process to form the fourth molybdenum target blank; after the hot rolling process, The fourth molybdenum target blank is annealed to form a molybdenum target. Using the above-mentioned manufacturing method of the molybdenum target, a fully dense molybdenum target can be manufactured. The uniformity of the internal structure of the molybdenum target and the grain size and purity And the surface size meets the increasingly demanding sputtering process.

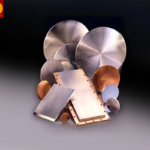

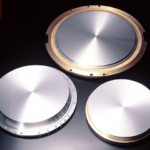

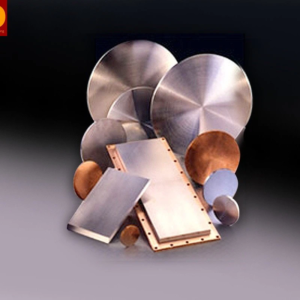

Welding method of molybdenum sputtering target

Provide molybdenum or molybdenum alloy target material, back plate and solder; nickel-plating the bonding surface of molybdenum or molybdenum alloy target material; preheat the molybdenum or molybdenum alloy target material so that the solder is distributed on the molybdenum or molybdenum alloy target The bonding surface of the alloy target; preheat the back plate to distribute the solder on the bonding surface of the back plate; make the bonding surface of the molybdenum or molybdenum alloy target and the bonding surface of the back plate adhere and merge Perform welding to form the target component; cool the target component. According to this molybdenum target welding method, the molybdenum or molybdenum alloy target and the backing plate, especially the copper backing plate, can be combined with higher strength to meet the high-strength requirements of the sputtering process; and even if the target area is relatively large If it is large, it can also effectively suppress the target assembly, especially the molybdenum or molybdenum alloy target from large deformation, warpage, etc.

Other alloy forms of molybdenum sputtering target

Molybdenum titanium, molybdenum sodium, molybdenum niobium, molybdenum-tantalum alloy targets, etc.