Tungsten, Molybdenum boat for Thermal Evaporation Deposition

Thermal evaporation (resistance evaporation) is a coating method used as part of the PVD process (Physical Vapor Deposition). The material that is to form the subsequent layer is heated in a vacuum chamber until it evaporates. The vapor formed by the material condenses on the substrate and forms the required layer.

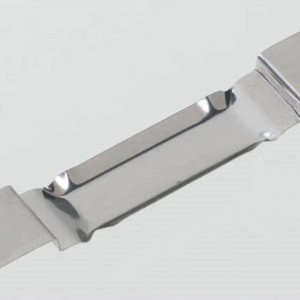

Alongside evaporation coils, we also manufacture boats and liners to collect the material as it evaporates. Why? Our boats and crucibles made from molybdenum, and tungsten, offer good electrical conductivity coupled with reduced vapor pressures and very high melting points. When powered on, our boats heat the material for evaporation. The low vapor pressures involved ensure that no tungsten or molybdenum particles enter the vapor.

The result: Gleaming watches, flawless mirrors, and top-quality electronic components. You can be assured of long service lives and a high level of dimensional accuracy. Benefiting from our extensive experience, we have the expertise to optimize the material and geometries of our evaporation boats to perfectly align with your specific process requirements. Our team would be more than happy to advise you in selecting the right boat for your process.

- Product: Tungsten and Molybdenum Boat

- Impurity content: ≤0.04%

- W/Mo Content: ≥99.95%

- Technique: Extruding, forging, rolling, machining, sintering

- Size: (2.5 to 100mm) H x (15 to 900mm) W x (15 to 900mm) L x (0.25 to 8mm) Thk

We can produce molybdenum, tungsten, and tantalum boats according to your requirements.