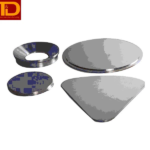

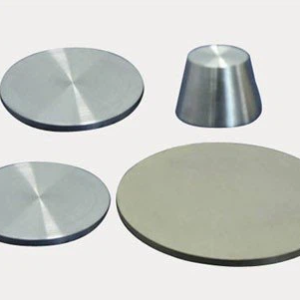

Rhenium Tungsten Targets

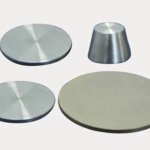

Rhenium tungsten targets are specialized materials used in the production of X-ray tubes for medical imaging and industrial applications. These targets consist of a combination of rhenium and tungsten, which are chosen for their high melting points and excellent thermal conductivity. The alloy’s robust properties make it suitable for withstanding the intense heat generated during X-ray tube operation, ensuring durability and stability in medical diagnostic equipment and industrial X-ray systems.

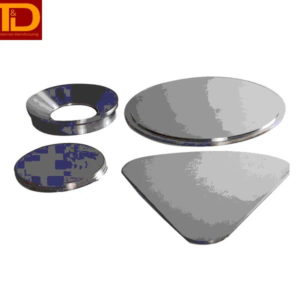

Tungsten-rhenium ratio: WRe 3%, WRe 5%, WRe 25%, WRe 26%

Size range: Thickness 0.2-20mm, max width 500mm, max length 100mm

Tungsten boasts a high melting point and the ability to generate X-rays when irradiated by a high-speed electron beam. Consequently, it finds frequent application as the X-ray source in various X-ray tubes. Additionally, tungsten-rhenium target material is favored for its exceptional attributes such as high strength, toughness, heat resistance, and precision. This material can effectively accommodate high-power electron beams, making it a common choice in medical X-ray tubes. Additionally, tungsten-rhenium targets are extensively employed in magnetron sputtering processes.

Manufacturing Capabilities

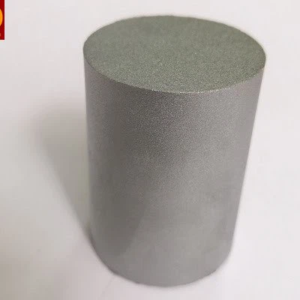

T&D is a certified domestic supplier adhering to ISO9001:2015 standards, specializing in providing Tungsten Carbide, Heavy Tungsten Alloy, Copper Tungsten, Tungsten, Molybdenum, Tantalum, and Niobium in the form of either semi-finished blanks or precision-machined parts. We offer customized machining services tailored to your specifications based on provided technical drawings. Our capabilities extend to prototyping as well as low-to-high volume production runs, ensuring comprehensive support for your specific requirements.

T&D Materials Manufacturing leverages modern equipment, cost-effective processes, and efficient lead times to offer customers high-quality products and exceptional customer service. Our capabilities encompass direct pressing and Metal Injection Molding (MIM), CNC preforming, Hot Isostatic Pressing (HIP) sintering for consistently high strength, and fully automated CNC finishing to achieve close tolerances and superior finishes.

All our tungsten and tantalum raw materials come from ”Conflict-Free” sources.

ITAR Compliant

T&D Materials Manufacturing Produces all products meeting industry standards of ISO, ASTM, ASM, MIL, and custom grades.

Purchasing options include blanket orders, just-in-time delivery, and consignment materials. If you are looking for high-quality W/Mo/Ta/Nb/WC/WCu/Re products, contact us today at 484-472-6863 or info@TDmfginc.com