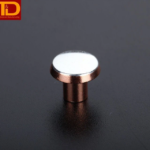

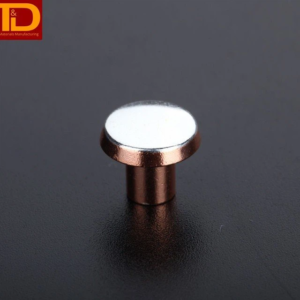

Silver Tungsten Contacts

Silver tungsten contacts are composite materials commonly used in electrical switches and relays due to their excellent combination of electrical and mechanical properties. These contacts offer enhanced conductivity from silver and improved durability and resistance to arcing and welding from tungsten. This combination makes silver tungsten contacts suitable for demanding applications where reliable and efficient electrical switching is crucial, for example industrial machinery, automotive components, and power distribution systems.

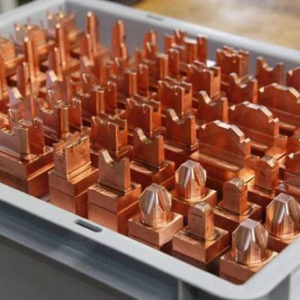

Silver tungsten alloy is a binary composition comprising tungsten and silver. Due to tungsten’s exceptionally high melting point, conventional smelting methods are impractical for achieving miscibility with silver. At T&D, we employ powder metallurgy technology to create silver tungsten alloys. This involves mixing silver and tungsten powders, followed by die-casting molding utilizing isostatic pressing technology. Subsequently, we employ vacuum high-temperature sintering to produce qualified products, which undergo final refinement through mechanical processing.

Features and application

Silver tungsten alloy exhibits elevated hardness, resistance to arc erosion, and excellent anti-gelling and anti-fusion welding ability. It finds extensive application in high-temperature resistant materials, high-voltage switches, microelectronic materials, and electrode materials for electric processing. Alloys with tungsten content exceeding 60% are typically manufactured using the penetration method. These alloys are employed in various applications such as low-voltage power switches, large current switch contacts, heavy-load relays, air circuit breakers, and more.

Chemical composition and physical properties

| Symbol | Chemical composition (%) | Physical properties | ||||||

| Ag | Total impurities (≤) | W | Density g/cm3

(≥) |

Hardness HB

(≥) |

Resistivity nΩ·cm

(≤) |

Conductivity IACS/%

(≥) |

Bending strength MPa

(≥) |

|

| AgW(30) | 70±1.5 | 0.5 | Bal | 11.75 | 75 | 2.3 | 75 | – |

| AgW(40) | 60±1.5 | 0.5 | Bal | 12.40 | 85 | 2.6 | 66 | – |

| AgW(50) | 50±1.5 | 0.5 | Bal | 13.15 | 105 | 3.0 | 57 | – |

| AgW(55) | 45±1.5 | 0.5 | Bal | 13.55 | 115 | 3.2 | 54 | – |

| AgW(60) | 40±1.5 | 0.5 | Bal | 14.00 | 125 | 3.4 | 51 | – |

| AgW(65) | 35±1.5 | 0.5 | Bal | 14.50 | 135 | 3.6 | 48 | – |

| AgW(70) | 30±1.5 | 0.5 | Bal | 14.90 | 150 | 3.8 | 45 | 657 |

| AgW(75) | 25±1.5 | 0.5 | Bal | 15.40 | 165 | 4.2 | 41 | 686 |

| AgW(80) | 20±1.5 | 0.5 | Bal | 16.10 | 180 | 4.6 | 37 | 726 |

Testing

- Chemical composition test

- Physical properties test

- Conductivity detection

- Appearance size detection

- Metallography detection

Packing

Products are enclosed in plastic film to prevent friction or collisions, ensuring the product’s integrity. Additionally, the external packaging is done using wooden cases.