Silver Tungsten for EDM and ECM

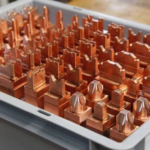

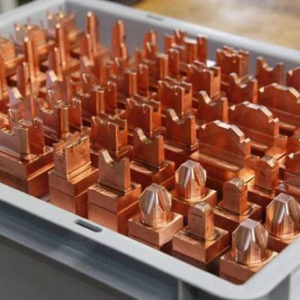

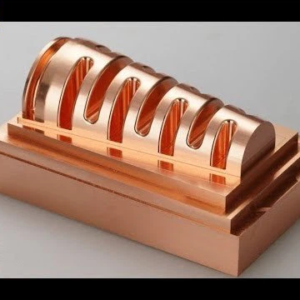

Silver tungsten is a composite material widely utilized in Electrical Discharge Machining (EDM) and Electrochemical Machining (ECM) applications due to its exceptional electrical and thermal conductivity properties. This alloy combines the high conductivity of silver with the hardness and wear resistance of tungsten, making it ideal for use in electrodes. In EDM, silver tungsten electrodes efficiently remove material through spark erosion, while in ECM, the material’s robustness and conductivity contribute to precise and efficient metal removal processes, enhancing overall machining performance and durability.

Silver tungsten alloy is a binary composition comprising tungsten and silver. Due to tungsten’s exceptionally high melting point, conventional smelting methods are impractical for achieving miscibility with silver. At T&D, we employ powder metallurgy technology to create silver tungsten alloy. This involves mixing silver and tungsten powders, followed by die-casting molding utilizing isostatic pressing technology. Subsequently, we employ vacuum high-temperature sintering to produce qualified products, which undergo final refinement through mechanical processing.

Features And Application

Silver tungsten alloy exhibits elevated hardness, resistance to arc erosion, and excellent anti-gelling and anti-fusion welding ability. It finds extensive application in high-temperature resistant materials, high-voltage switches, microelectronic materials, and electrode materials for electric processing. Alloys with tungsten content exceeding 60% are typically manufactured using the penetration method. These alloys are employed in various applications such as low-voltage power switches, large current switch contacts, heavy-load relays, air circuit breakers, and more.

Chemical composition and physical properties

| Symbol | Chemical composition (%) | Physical properties | ||||||

| Ag | Total impurities (≤) | W | Density g/cm3

(≥) |

Hardness HB

(≥) |

Resistivity nΩ·cm

(≤) |

Conductivity IACS/%

(≥) |

Bending strength MPa

(≥) |

|

| AgW(30) | 70±1.5 | 0.5 | Bal | 11.75 | 75 | 2.3 | 75 | – |

| AgW(40) | 60±1.5 | 0.5 | Bal | 12.40 | 85 | 2.6 | 66 | – |

| AgW(50) | 50±1.5 | 0.5 | Bal | 13.15 | 105 | 3.0 | 57 | – |

| AgW(55) | 45±1.5 | 0.5 | Bal | 13.55 | 115 | 3.2 | 54 | – |

| AgW(60) | 40±1.5 | 0.5 | Bal | 14.00 | 125 | 3.4 | 51 | – |

| AgW(65) | 35±1.5 | 0.5 | Bal | 14.50 | 135 | 3.6 | 48 | – |

| AgW(70) | 30±1.5 | 0.5 | Bal | 14.90 | 150 | 3.8 | 45 | 657 |

| AgW(75) | 25±1.5 | 0.5 | Bal | 15.40 | 165 | 4.2 | 41 | 686 |

| AgW(80) | 20±1.5 | 0.5 | Bal | 16.10 | 180 | 4.6 | 37 | 726 |

Testing

- Chemical composition test

- Physical properties test

- Conductivity detection

- Appearance size detection

- Metallography detection

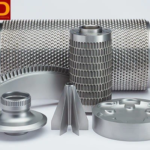

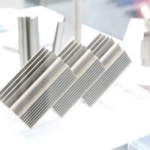

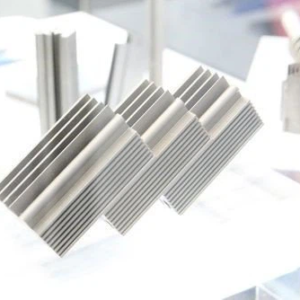

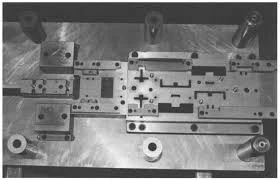

Manufacturing Capabilities

A domestically certified supplier adhering to ISO 9001:2015 standards, offering Tungsten Carbide, Heavy Tungsten Alloy, Copper Tungsten, Tungsten, Molybdenum, Tantalum, and Niobium. We provide either semi-finished blanks or precision-machined parts, your order can be tailored to your exact specifications based on your technical drawings. Our services include prototyping and catering to low-to-high volume production runs.

Modern equipment, low costs, and short lead times allow T&D Materials Manufacturing to provide its customers with quality products and excellent customer service. Our capabilities include direct pressing and MIM, CNC pre-forming, and HIP sintering to assure consistently high strength, and fully automated CNC finishing to close tolerances and superior finishes.

All our tungsten and tantalum raw materials come from ”Conflict-Free” sources.

ITAR Compliant

T&D Materials Manufacturing ensures that all our products adhere to industry standards such as ISO, ASTM, ASM, MIL, and custom grades. Purchasing options include blanket orders, just-in-time delivery, and consignment materials. For inquiries about premium W/Mo/Ta/Nb/WC/WCu/WAg/Re products, feel free to reach out to us today at 484-472-6863 or info@TDmfginc.com.