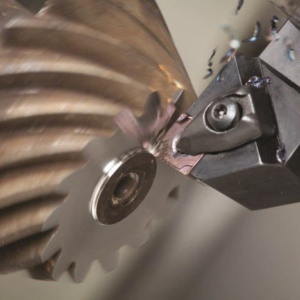

Tungsten Carbide Metal Cutting Tools

Carbide cutting tools, alternatively referred to as cemented carbide cutting tools or tungsten carbide cutting tools, stand as the leading products of CNC machining tools. In some countries, over 90% of turning tools and 55% of milling tools are made of cemented carbide, with this inclination on the rise.

Tungsten carbide cutting tools exhibit attributes such as exceptional hardness, strength, wear resistance, and modulus of elasticity, coupled with notable impact toughness and corrosion resistance. Comprising mainly WC and Co, carbide cutters generally come in two types: solid carbide and welded edge. T&D focuses on solid carbide end mills, solid carbide drill bits, and solid carbide inserts.

Based on the hardness of the workpiece, tungsten carbide drill bits, carbide end mills, and carbide inserts are categorized into various series. Standard sizes are ideal for general applications in CNC machines, and at T&D, we maintain a substantial stock of these standard items for prompt, quick delivery. For non-standard sizes and precise industrial blades like plotter blades and wire stripping blades, custom drawings are needed to meet specific requirements.

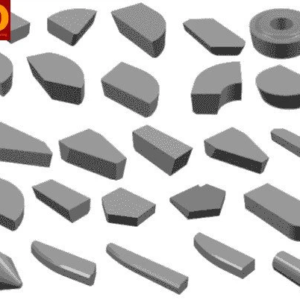

Carbide Insert

Carbide inserts, also referred to as CNC blades or indexable carbide inserts, stand out as a leading product in contemporary metal cutting applications. Primarily employed in metal turning, milling, groove cutting, thread turning, and more, these inserts are categorized based on their functions as turning inserts, milling inserts, and threading inserts.

Carbide End Mills

The workpiece hardness plays a pivotal role in end mill selection, with standard end mills categorized for HRC 45, 50, 55, and 60, catering to milling needs such as special aluminum milling and stainless steel milling. Each category further includes three subcategories based on end shape: flat end mill (square end mill), ball end mill, and corner radius end mill.

Carbide Drill Bit

In the drilling process sequence, carbide drill bits can be categorized into pilot drill bits, center drill bits, twist drill bits, and spot-facer drill bits (countersink drill bits). Additionally, based on the coolant method, there are external cooling drill bits and inner cooling drill bits with coolant holes. When drilling depths surpass 3D and extend to 5D or beyond, internal cooling can greatly enhance efficiency and prolong the service life of the drill.

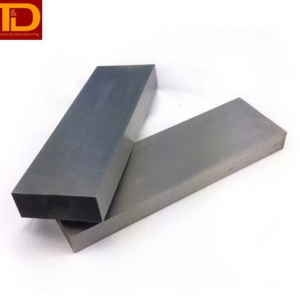

Industrial Blade

Cemented carbide finds extensive use in industrial blades that demand an exceptionally sharp edge and wear resistance due to its superior hardness (typically exceeding HRA 90 for blades). Examples of applications include plotter blades, woodworking blades, metal shear blades, and wire stripping blades.