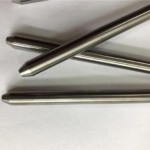

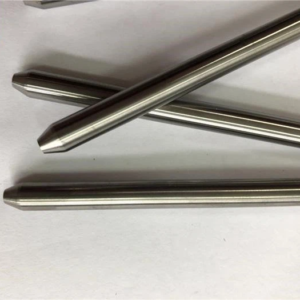

Tungsten Carbide Nozzles for WaterJet Cutting

Tungsten carbide nozzles are essential components in waterjet cutting systems, renowned for their exceptional hardness, durability, and wear resistance. Composed of tungsten and carbon, these nozzles exhibit remarkable abrasion resistance, ensuring prolonged service life even when exposed to highly abrasive cutting materials. The hardness of tungsten carbide also enables precise and efficient cutting, making it a preferred choice for applications requiring intricate designs and fine detailing in waterjet cutting processes.

We provide carbide nozzles that exhibit exceptional wear resistance, available in various outer diameters (OD), inner diameters (ID), and lengths tailored to your specifications. The content of blinders in these nozzles ranges from 0.25% to 0.40%.

Explore our extensive range of tungsten carbide micro-grain and sub-micron grades, each processed through sinter-HIP technology to guarantee comprehensive metallurgical integrity and manufacturing excellence within ISO 9001 certified facilities.

Dimensions:

| OD | ID | L |

| mm | mm | mm |

| 6.00 | 0.76 | 76.20 |

| 6.00 | 0.80 | 70.00 |

| 6.00 | 1.02 | 70.00 |

| 6.00 | 1.02 | 76.02 |

| 6.35 | 0.50 | 76.20 |

| 6.35 | 0.60 | 76.20 |

| 6.35 | 0.76 | 50.80 |

| 6.35 | 0.76 | 76.20 |

| 6.35 | 1.02 | 50.80 |

| 6.35 | 1.02 | 76.20 |

| 6.35 | 1.14 | 76.20 |

| 6.35 | 1.20 | 76.20 |

| 6.69 | 0.76 | 76.20 |

| 6.69 | 1.02 | 76.20 |

| 6.70 | 1.00 | 70.00 |

| 7.14 | 0.50 | 76.20 |

| 7.14 | 0.75 | 101.60 |

| 7.14 | 1.02 | 101.60 |

| 7.62 | 1.02 | 76.20 |

| 7.62 | 1.27 | 76.20 |

| 7.97 | 1.07 | 101.60 |

| 7.97 | 0.50 | 101.60 |

| 9.43 | 0.50 | 76.20 |

| 9.43 | 0.76 | 76.20 |