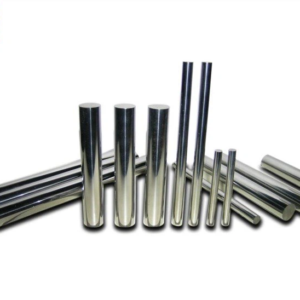

Tungsten Carbide Round Bars

Tungsten carbide rods play a vital role in creating top-notch carbide cutting tools for machining heat-resistant alloys and Ti alloys, such as end mills, drills, and reamers. Our selection includes carbide rods with h6 ground, Tungsten Alloy Rods with a chamfered end, sintered solid Tungsten Carbide Rod Blanks, and Tungsten Rod Stock with a straight hole.

Tungsten carbide rods find application in the production of various tools such as drill bits, end mills, reamers, automobile specialized cutters, printed circuit boards specialized cutters, engine specialized cutters, horology processing specialized cutters, integral vertical milling cutters, and gravers. Additionally, they are utilized for making cemented carbide stamping heads, core bars, and perforation tools. We offer both sintered blanks and ground tungsten carbide welding rods.

Key Features:

1. Sintered or mirror-polished to h6

2. Carbide Rods in various grades and sizes

3. Large stock for regular dimensions

4. Complete inspecting and testing equipment

Grade of Tungsten Carbide Rod Application Recommendation:

| Grade | Grain Size (um) | Density (g/cm³) | Hardness HRA | T.R.S N/mm² | Recommended Use |

| LX25 | 0.8 | 14.4 | 91.5 | 3600 | Used for making general-purpose drills and endmills, especially for common alloy steel (HRC < 50), grey cast iron, heat-resistant alloys, etc. |

| LBC25 | 0.6 | 14.1 | 92.5 | 3800 | Used for making general-purpose drills and endmills, especially for heat-resistant alloys, stainless steel, cast iron, etc. |

| R30 | / | 13.95 | 85 | 4000 | They are widely used in punch, pin, forming mandrel, powder metallurgy core, mandrel, etc. |

Commonly Used Grades of Tungsten Carbide Rods:

| Grade | Equivalent to ISO | Density(g/cm³) | Bending strength is not less than (N/cm²) | Hardness not less than HRA | Physical and mechanical properties and recommended use |

| YG3X | K01 | 14.6-15.2 | 1320 | 92 | It is suitable for high-speed finishing of small cutting sections of cast iron, non-ferrous metals, and alloy hardened steel alloy steel. |

| YG6A | K05 | 14.6-15.0 | 1370 | 91.5 | It is suitable for the semi-finishing of hard cast iron, non-ferrous metals, and their alloys, as well as the semi-finishing and finishing of high manganese steel, quenched steel, and alloy steel. |

| YG6X | K10 | 14.6-15.0 | 1420 | 91 | It has been proved by production and use that the alloy can obtain good results when processing chilled alloy cast iron and heat-resistant alloy steel. It is also suitable for the finishing of ordinary cast iron. |

| YK15 | K15 | 14.2-14.6 | 2100 | 91 | It is suitable for processing integral alloy drilling, milling, reaming, and other cutting tools. Has high wear resistance and toughness. |

| YG6 | K20 | 14.5-14.9 | 1380 | 89 | It is suitable for the second half of finishing with a medium cutting speed of cast iron, non-ferrous metals, and alloy non-metal materials. |

| YG6X-1 | K20 | 14.6-15.0 | 1500 | 90 | Suitable for fine turning in the continuous cutting of cast iron, non-ferrous metals, and their alloy non-metallic materials, semi-finishing turning, finishing turning, small turning finishing, rough turning thread, semi-finishing and finishing milling of continuous sections, holes in discontinuous cutting, holes Rough expansion and precision expansion. |

| YG8N | K30 | 14.5-14.8 | 2000 | 90 | Suitable for high-speed cutting of cast iron, white cast iron, nodular cast iron, and alloy materials such as chromium and nickel stainless steel. |

| YG8 | K30 | 14.5-14.9 | 1600 | 89.5 | It is suitable for rough turning, rough planing, and rough milling of uneven sections and intermittent cutting in the processing of cast iron, nonferrous metals and their alloys and non-metallic materials, drilling and reaming of general holes, and deep holes. |

| YG10X | K35 | 14.4-14.7 | 2200 | 89.5 | It is suitable for manufacturing fine-diameter micro-drills, end mills, rotary files, etc. |

| YS2T | K30 | 14.4-14.6 | 2200 | 91.5 | It is an ultra-fine grain alloy, suitable for low-speed rough turning, and milling of heat-resistant alloys and titanium alloys, and is particularly suitable for cutting cutters, taps, and saw blade milling cutters. |

| YL10.1 | K15-K25 | 14.9 | 1900 | 91.5 | It has good wear resistance and flexural strength. It is mainly used for the production of extruded bars and is suitable for wear-resistant parts such as general drills and cutters. |

| YL10.2 | K25-K35 | 14.5 | 2200 | 91.5 | It has good wear resistance and bending strength. It is mainly used to produce extruded bars, small-diameter micro drills, cutting tools for clocks and watches, integral reamers and other cutting tools and wear-resistant parts. |

| YG15 | / | 13.9-14.2 | 2100 | 87 | It is suitable for upsetting, piercing, and punching tools for steel rod and steel tube drawing under a high compression ratio and working under large stress. |

| YG20 | / | 13.4-13.7 | 2500 | 85 | Suitable for making stamping dies, such as stamping watch parts, musical instrument springs, etc.; stamping dies for punching battery shells, toothpaste skins; stamping dies for small-sized steel balls, screws, nuts, and hot-rolled twist drill press plates. |

- Superior raw carbide material with high wear resistance and good corrosion resistance, durable with high service life.

- Consistent quality is ensured through rigorous quality control following thorough inspection and testing of equipment.

- Highly efficient anti-shake with robust rigidity.

- Precision tolerance to the specified shape and size.

- Large stock of standard dimensions available for quick delivery.