Tungsten Contacts for Electrical Appliances

Currently, common control electrical products such as AC contactors, electromagnetic relays, electrical switches, and air switches all incorporate electrical contacts, which are among the most important components of these products.

The reliability and service life of the product depend mostly on the contact’s performance which is affected by factors such as contact material, load type, contact pressure, operating frequency, and use environment. When these factors cannot meet the working requirements, problems such as electrochemical corrosion of contacts, welding between contacts, contact wear, and an increase in contact resistance will occur. Which will lead to unreliable operation, functional failure, and even potential safety hazards.

In the energized state, if the current that opens the circuit exceeds a certain limit, or if the voltage on the contact gap exceeds a certain limit after the opening, the contact gap will appear. Under the action of a strong electric field, the gas between the contacts will discharge. Sparks and strong light will be generated and emitted with an increase in the temperature. The arc will corrode the metal surface of the contact, shorten the service life of the electrical appliance, extend the breaking time of the circuit, and cause contact failure. In severe cases, it can also cause fire accidents.

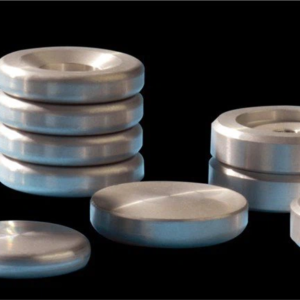

Nowadays, to further improve the overall quality of electrical equipment contact points, most manufacturers use metal tungsten to make electrical contacts.

Our specialty tungsten contacts are manufactured as per the international standards of quality. The raw materials used are exclusively procured from highly reputed and reliable manufacturers. Right from the procurement of the raw materials to the final product delivery, we have instituted stringent quality control measures under the supervision of experienced quality control personnel.

T&D is certified with ISO 9001:2008 quality standards by Intertek-Systems.