T&D supplies high-quality rhenium heater filaments for the MOCVD Industry including the D125, D180, and D300 units. We also supply Rhenium filaments to any customer’s desired specifications or thicknesses.

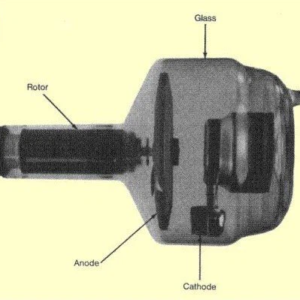

MOCVD is an epitaxial process for creating crystalline semiconductor layers for LEDs, solar cells, and other optoelectronic components. MOCVD stands for metal-organic chemical vapor phase deposition.

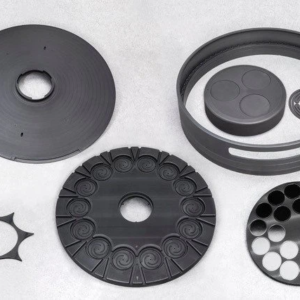

In an MOCVD system, the heating elements need to reach temperatures as high as 2000 degrees. These extreme temperatures necessitate the use of our high-performance materials, molybdenum, and tungsten, for various components like shield packs, gas manifolds, and heating elements. T&D offers a variety of components for MOCVD, including spare parts made from tungsten and molybdenum.

Our improved technical designs and patented coatings mean that our products are far more than just spares for our customers.

The semiconductor layers in an LED should emit light of the same wavelength as far as possible. One important prerequisite for this is a homogeneous temperature distribution in the MOCVD system. Any discrepancy in the temperature profile will subsequently lead to a change in the color of the emitted light. Our engineers carry out complex finite element calculations to simulate the MOCVD process in each of the systems and optimize the design of our heating components. The new components deliver a more homogeneous temperature throughout the reactor. The customer experiences enhanced productivity due to a higher yield obtained in each coating cycle.