Tungsten mesh heating elements offer an ultra-clean heating source in controlled atmosphere applications.

Tungsten mesh heating elements have an upper-temperature operating range of 3,000°C (3,273°K) in an inert atmosphere;

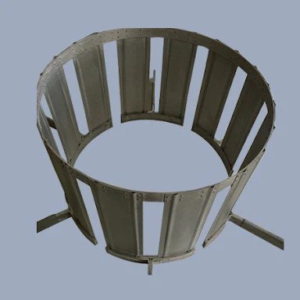

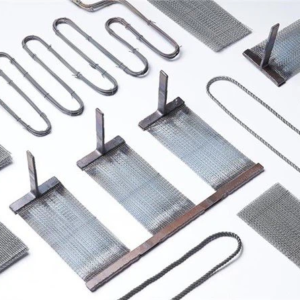

In tungsten mesh heating elements, the element wires are wound around a mandrel to create concentric coils of wire. The coils are twisted into each other, which forms the mesh. The ends of the wires are sandwiched between solid bands made of tungsten. The interlacing of the wires in the panel design allows the individual wires to move during the heat cycles without binding and/or breaking against each other.

The elements are custom-designed for each application. Resistance is a design factor that can be adjusted to maximize efficiency. The power leads and top and bottom bands are also key factors in the design. The tungsten mesh element can be a circular or a flat panel, and they can be manufactured for a single- or three-phase power operation. Most heating elements hang vertically, although some are operated horizontally. The position of the element becomes a design factor. The heating elements are generally supported by liquid-cooled power feedthroughs. The style and position of the feedthroughs determine the style of power leads (round rods or flat bars are most common).