Tungsten Alloy

Physical Properties

- Density: Typically ranges from 16 g/cm³ to 19 g/cm³, depending on the composition

- Melting Point: Lower than pure tungsten but still high, generally above 2500°C (4532°F)

- Thermal Conductivity: High, although it varies based on alloying elements

- Electrical Conductivity: Improved compared to pure tungsten due to alloying elements

- Hardness: High, but can be tailored for specific applications through alloying

Chemical Properties

- Oxidation States: +5 (most common), +3

- Electronegativity: 1.5 (Pauling scale)

- Reactivity: Tantalum is highly resistant to corrosion due to the formation of a stable oxide layer.

- Corrosion Resistance: Exceptional resistance, particularly to acids.

Overview

Tungsten alloys are materials composed of tungsten and various other elements, such as nickel, iron, copper, and cobalt, to improve their mechanical and physical properties. These alloys leverage tungsten’s exceptional properties, such as its high melting point and density, and combine them with other metals to enhance characteristics like ductility, machinability, and thermal and electrical conductivity. Tungsten alloys are widely used in aerospace, military, medical, and industrial applications.

Uses of Tungsten Alloy

Tungsten alloys are used in various high-tech, industrial, and medical applications due to their unique combination of properties.

Aerospace & Military Applications

- Aerospace Components: Used in the production of high-temperature and high-stress components, such as rocket nozzles and turbine blades.

- Armor-Piercing Ammunition: High-density tungsten alloys are used in military projectiles and kinetic energy penetrators.

- Radiation Shielding: Provides effective radiation protection in aerospace and military applications.

Medical Applications

- Radiation Shielding: Used in medical imaging devices and radiation therapy equipment to protect against radiation.

- Medical Devices: Employed in various medical devices that require high density and biocompatibility.

Industrial Applications

- Cutting Tools and Wear Parts: Tungsten alloys are used to manufacture cutting tools, mining equipment, and other wear-resistant parts.

- Heat Sinks: Due to their excellent thermal conductivity, tungsten-copper alloys are used in electronic devices to dissipate heat.

- Electrical Contacts: Tungsten alloys are used in electrical contacts and electrodes due to their good conductivity and resistance to arc erosion.

Advantages & Disadvantages of Tungsten Alloy

Advantages

- High Density: Ideal for applications requiring significant weight and compactness.

- High Melting Point: Suitable for high-temperature environments.

- Strength and Hardness: Provides excellent mechanical properties for cutting and wear-resistant applications.

- Thermal and Electrical Conductivity: Enhanced by alloying elements, making them suitable for thermal management and electrical applications.

- Corrosion Resistance: Improved with specific alloying elements, making them durable in harsh environments.

Disadvantages

- Cost: Relatively expensive due to the cost of tungsten and the complex manufacturing processes.

- Machining Difficulty: Can be challenging to machine, although alloying improves machinability compared to pure tungsten.

- Brittleness: Pure tungsten can be brittle, but alloying helps mitigate this issue.

Physical & Chemical Properties of Tungsten Alloy

| Property | Value |

|---|---|

| Density | 16-19 g/cm³ |

| Melting Point | >2500°C (4532°F) |

| Thermal Conductivity | High |

| Electrical Conductivity | Improved compared to pure tungsten |

| Hardness | High, varies with composition |

| Oxidation Resistance | Enhanced |

| Corrosion Resistance | Good |

Major Applications of Tungsten Alloy

| Application Area | Examples |

|---|---|

| Aerospace and Military | Aerospace components, armor-piercing ammunition, radiation shielding |

| Medical | Radiation shielding, medical devices |

| Industrial | Cutting tools, heat sinks, electrical contacts |

Tungsten alloys are critical in numerous advanced applications due to their unique properties, including high density, high melting point, and excellent mechanical strength. Their use in aerospace and military applications demonstrates their capability to perform under extreme conditions, providing durability and reliability. In the medical field, tungsten alloys offer effective radiation shielding and are used in various medical devices. Industrial applications benefit from the alloys’ wear resistance and thermal conductivity, making them ideal for cutting tools and heat sinks. Despite their higher cost and machining challenges, the exceptional properties of tungsten alloys ensure their continued demand and utilization in high-performance and critical applications.

Tungsten Alloy Products

Tungsten Alloy for Medical Imaging

Read more

Tungsten Alloy for Nuclear Reactor

Read more

PET & SPECT Tungsten Alloy Syringe Shield

Read more

PET & SPECT Tungsten Alloy Vial Shields

Read more

Tungsten Silicone

Read more

Tungsten Alloy for CT Scanner

Read more

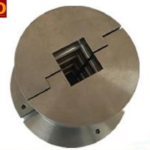

Tungsten Alloy Collimator

Read more

Tungsten Alloy Eye & Ear Shields

Read more