Tungsten Carbide

Physical Properties

- Density: 15.63 g/cm³

- Melting Point: 2870°C (5198°F)

- Hardness: 9 on the Mohs scale, Vickers hardness of 1700-2400 kg/mm²

- Tensile Strength: 344 MPa (50,000 psi)

- Compressive Strength: 6800 MPa (1,000,000 psi)

- Thermal Conductivity: 84 W/m·K

Chemical Properties

- Chemical Formula: WC

- Oxidation Resistance: Excellent at high temperatures, but can oxidize in air at temperatures above 500°C

- Corrosion Resistance: Highly resistant to acids and alkalis, except for strong oxidizing acids

- Reactivity: Reacts with chlorine gas at high temperatures

Overview

Tungsten carbide (WC) is a chemical compound made of tungsten and carbon atoms in equal parts. Known for its extreme hardness and high melting point, tungsten carbide is a valuable material in industrial applications where strength and durability are essential. It is produced by combining tungsten and carbon powders and sintering them at high temperatures.

Uses of Tungsten Carbide

Tungsten carbide is utilized in various applications that require materials with exceptional hardness, wear resistance, and the ability to withstand high temperatures.

Cutting Tools & Wear Parts

- Machine Tools: Tungsten carbide is used in milling, drilling, and turning tools due to its ability to cut through tough materials.

- Mining and Construction: Employed in drill bits, crushers, and trenchers for its durability and wear resistance.

- Metalworking: Utilized in cutting, grinding, and forming tools in metal fabrication.

Jewelry & Fashion

- Rings and Watches: Tungsten carbide is popular in the jewelry industry for making rings and watch bands due to its hardness and scratch resistance.

Industrial Applications

- Wear-Resistant Parts: Used in valves, nozzles, and seals in industries like oil and gas, aerospace, and automotive.

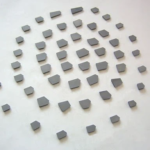

- Milling and Crushing Equipment: Tungsten carbide is used in milling balls, hammers, and anvils for its durability and ability to withstand high-impact applications.

- Abrasives: Used in abrasive wheels and belts for grinding hard materials.

Military & Defense

- Armor-Piercing Projectiles: Utilized in the production of ammunition that can penetrate armored vehicles due to its density and hardness.

- Armor Plating: Used in personal and vehicle armor for enhanced protection.

Advantages & Disadvantages of Tungsten Carbide

Advantages

- Extreme Hardness: One of the hardest known materials, second only to diamond.

- Wear Resistance: Exceptional resistance to wear and abrasion, extending the lifespan of tools and components.

- High Melting Point: Suitable for high-temperature applications.

- Corrosion Resistance: Excellent resistance to most acids and alkalis.

Disadvantages

- Brittleness: Can be brittle and susceptible to fracturing under high impact or stress.

- Cost: More expensive than many other materials due to the complex production process.

- Machining Difficulty: Requires specialized equipment and techniques for machining and shaping.

Physical & Chemical Properties of Tungsten Carbide

| Property | Value |

|---|---|

| Density | 15.63 g/cm³ |

| Melting Point | 2870°C (5198°F) |

| Hardness | 9 (Mohs scale), 1700-2400 kg/mm² (Vickers) |

| Tensile Strength | 344 MPa (50,000 psi) |

| Compressive Strength | 6800 MPa (1,000,000 psi) |

| Thermal Conductivity | 84 W/m·K |

| Chemical Formula | WC |

| Oxidation Resistance | High |

| Corrosion Resistance | High |

Major Applications of Tungsten Carbide

| Application Area | Examples |

|---|---|

| Cutting Tools and Wear Parts | Machine tools, mining equipment, metalworking tools |

| Industrial | Valves, nozzles, seals, milling equipment |

| Jewelry and Fashion | Rings, watch bands |

| Military and Defense | Armor-piercing projectiles, armor plating |

Tungsten carbide is an essential material in numerous industrial, technological, and even fashion applications due to its unparalleled hardness, wear resistance, and ability to perform under extreme conditions. Its use in cutting tools and wear parts underscores its importance in machining and metalworking industries, where it significantly enhances productivity and tool lifespan. In industrial settings, tungsten carbide’s durability and resistance to abrasion make it ideal for components exposed to harsh environments. The jewelry industry values tungsten carbide for its scratch resistance and aesthetic appeal, while the military benefits from its density and hardness in armor-piercing applications. Despite its brittleness and higher cost, the unique properties of tungsten carbide ensure its continued demand and utilization across a wide range of advanced and critical applications.

Tungsten Carbide Products

Tungsten Carbide Tool for Trenching

Read more

Tungsten Carbide Tips for Geological

Read more

Tungsten Carbide for Surface Mining

Read more

Tungsten Carbide Shanks

Read more

Tungsten Carbide Rock Bits for Air Drilling

Read more

Tungsten Carbide Nozzles for Oil Well Drilling Bits

Read more

Tungsten Carbide Mining Roof Bits

Read more

Tungsten Carbide Inserts for Drill Bits

Read more