Tungsten Silver Alloy

Overview

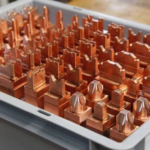

Tungsten silver alloy (W-Ag) combines the unique properties of tungsten and silver to create a composite material with high thermal and electrical conductivity, good corrosion resistance, and the ability to withstand high temperatures. This alloy is typically produced using powder metallurgy, where tungsten and silver powders are mixed, compacted, and sintered. The typical composition can vary, but commonly used alloys might contain 30-50% silver, with the remainder being tungsten.

Physical Properties

- Density: 12.0 – 15.0 g/cm³ (depending on composition)

- Melting Point: The alloy does not have a single melting point but rather a melting range influenced by the silver content, generally above 1000°C.

- Thermal Conductivity: 150 – 250 W/m·K (varies with composition)

- Electrical Conductivity: 40 – 60% IACS (International Annealed Copper Standard)

- Hardness: 150 – 300 HB (Brinell Hardness)

Chemical Properties

- Oxidation Resistance: Improved compared to pure silver due to the presence of tungsten.

- Corrosion Resistance: Excellent resistance to most corrosive environments; silver contributes to high corrosion resistance.

- Reactivity: Generally stable; silver can oxidize under certain conditions, but tungsten remains inert.

Uses of Tungsten Silver Alloy

Tungsten silver alloys are used in various applications where a combination of high electrical and thermal conductivity, high temperature resistance, and good mechanical properties are essential.

Electrical & Electronic Applications

- Electrical Contacts and Relays: Used in circuit breakers, electrical switches, and relays due to their excellent conductivity and resistance to arc erosion.

- Commutation Components: Employed in components of electrical machines that need to withstand significant wear and tear while maintaining conductivity.

- Electrodes: Utilized in applications requiring good conductivity and wear resistance, such as welding electrodes and spark plugs.

Aerospace & Defense

- High-Temperature Components: Used in aerospace applications where components must withstand high temperatures and thermal cycling.

- Radiation Shielding: Provides effective radiation protection for aerospace and defense applications, utilizing tungsten’s high density.

Thermal Management

- Implants and Surgical Instruments: Tantalum’s biocompatibility and resistance to corrosion make it ideal for medical implants and surgical instruments.

- Dental Applications: Used in dental prosthetics due to its inertness and durability.

Industrial Applications

- Machinery and Equipment: Used in parts that require high wear resistance and thermal stability, such as dies and molds in manufacturing processes.

- Thermal Management Systems: Used in industrial equipment that requires efficient heat dissipation and high-temperature stability.

Advantages & Disadvantages of Tungsten Silver Alloy

Advantages

- High Thermal Conductivity: Excellent for thermal management applications.

- High Electrical Conductivity: Suitable for electrical contacts and commutation components.

- High Melting Point: Can withstand high temperatures, making it suitable for high-temperature applications.

- Good Corrosion Resistance: Silver provides excellent resistance to corrosion in various environments.

Disadvantages

- Density: High density can be a drawback in applications where weight is a concern.

- Machining Difficulty: Requires specialized equipment and techniques for machining and shaping.

Physical & Chemical Properties of Tungsten Silver Alloy

| Property | Value |

|---|---|

| Density | 12.0 – 15.0 g/cm³ |

| Melting Point | >1000°C |

| Thermal Conductivity | 150 – 250 W/m·K |

| Electrical Conductivity | 40 – 60% IACS |

| Hardness | 150 – 300 HB |

| Oxidation Resistance | Improved compared to pure silver |

| Corrosion Resistance | Excellent |

Major Applications of Tungsten Silver Alloy

| Application Area | Examples |

|---|---|

| Electrical and Electronic | Electrical contacts, commutation components, electrodes |

| Thermal Management | Heat sinks, heat spreaders, cooling devices |

| Aerospace and Defense | High-temperature components, radiation shielding |

| Industrial | Machinery parts, thermal management systems |

Tungsten silver alloy is a versatile material used in applications requiring a combination of high thermal and electrical conductivity, high-temperature resistance, and good mechanical properties. Its use in electrical and electronic applications, such as electrical contacts and commutation components, showcases its exceptional performance in environments where efficient electrical and thermal management is crucial. In the aerospace and defense industries, the alloy’s high-temperature stability and radiation shielding capabilities are highly valued. Industrial applications benefit from the alloy’s durability and thermal management properties. Despite its higher cost and machining challenges, the unique properties of tungsten silver alloy ensure its continued demand and utilization in advanced technological and industrial fields.